Other Possible Table Construction Means and Methods:

The following information is provided to help in a custom table build. These images

demonstrate the recommended method for the table construction. The overall table

is a simple structure as the base with a shelf and the main table and surface is

is a torsion box table. The name torsion box describes the internal ribbing sandwiched

by two layers of boards. This technique of ribbing resists torsion (twisting) of

the table so that the entire table will be level in any direction.

To insure this the table will need a surface that is dead level. The best way to

do this is to use winding sticks and a level on a surface that can be leveled with

shims. Winding sticks are used to make sure there is no torsion existing in the

base when starting the construction. these winding sticks are placed at each end

of the board and just be looking at the two winding sticks from one end, the torsion

can be identified and corrected. This is best see in the videos from the Wood Whisperer or David Marks.

Torsion Box - as designed and built by David J. Marks

from Golem Online on Vimeo.

There are a couple of aspects that must be followed: The table must have a width

between 26-3/4" and 27", there must be an overhang of at least 1" (I recommend 1-1/2")

along the sides and there must be a clearance of 1-3/4" from the edge of the table

to the start of the rail.

In the image to the left, the table has a dimension of 6 feet by 2 feet and 2-3/4".

the 2' 2-3/4" is 26-3/4". This is a minimum dimension for the width so the gantry

will fit correctly.

The 6 feet can be longer or shorter; however, since the gantry side is about 17

inches in length, this takes away from the x-axis travel, so the table should be

at-least 18 inches longer in the x-axis direction. I recommend that 2 feet be added

to the x-axis length so there is some wiggle room at both ends.

The table length can be increase according to the desired x-axis travel length.

For example, if the desired x-axis travel is 8 feet, the table length should be

10 feet to compensate for the gantry structure.

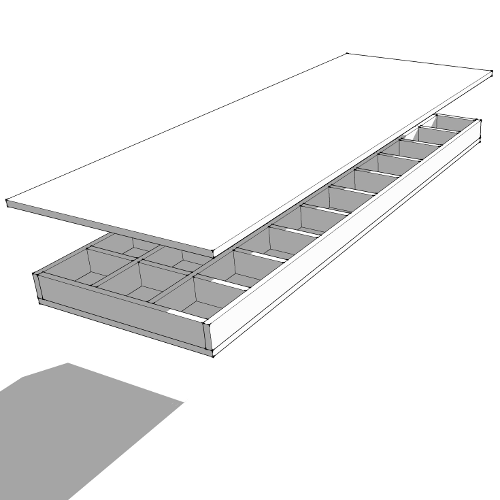

Since the x-axis rails need to be fastened to bot the top and bottom sides of the

table, the top surface should overhang 1-1/2" on both sides. This means that the

torsion box, or the structure just below the table surface should be a maximum of

23-3/4" so that this clearance can be established. The table top should be 3/4"

in thickness.

To make room for the parts that hold the x-axis chain, the rails should start 1-3/4"

from the edge of the table and provide the same clearance at the other end.

The following set of inages show one example of a table that would work as a base

for the 2x4 blackToe CNC Machine. There are many possible variations (table without

torsion box, cabinetry under table, etc.). This deminstrates an example for use

as a possible method, but I would encourage differernt table structures and features.

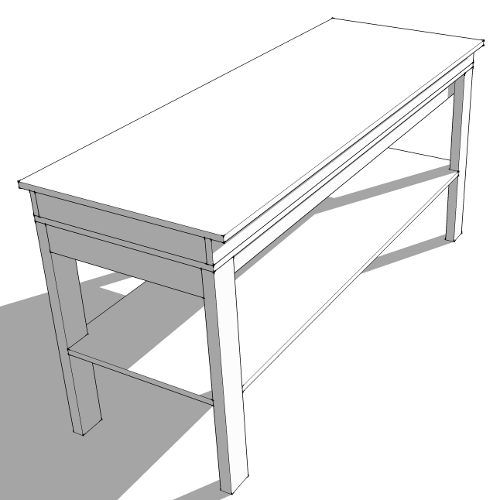

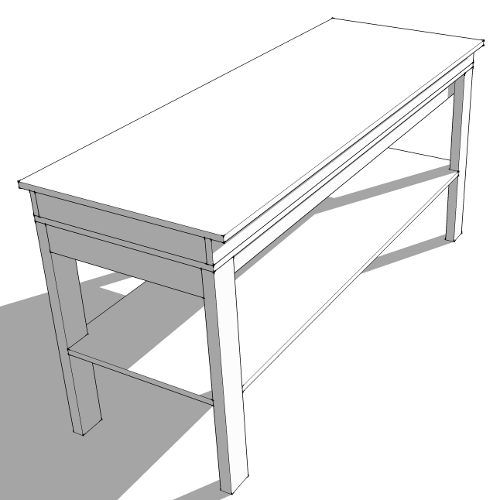

This is the table fully assembled. the talbe consists of standard 2x4 studs for

legs and frame. The middle shelf is used for storage and stability. More structure

underneath will stiffen the overall structure. just above the base is the torsion

box structure and table top.

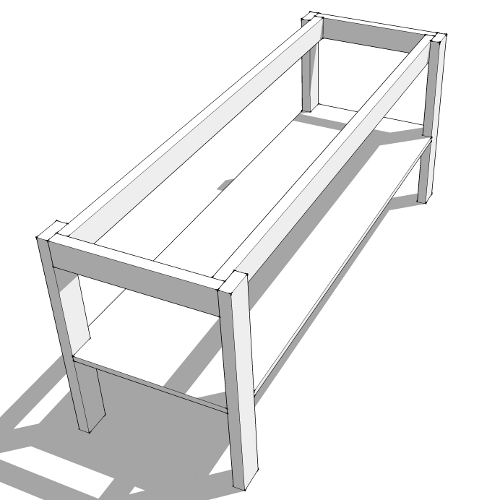

An exploded view of all table parts.

Table legs and frame.

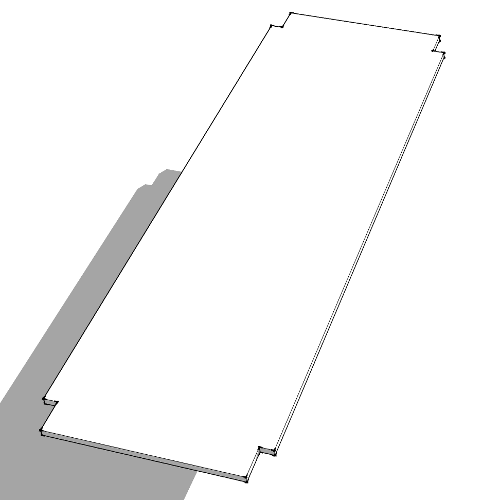

Shelf

Shelf and frame together.

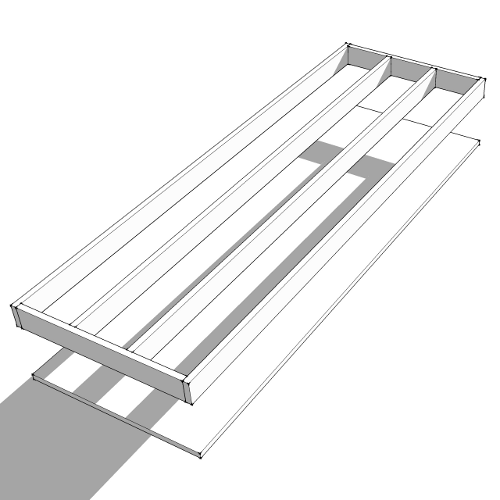

Torsion box - bottom layer and initial long ribbing.

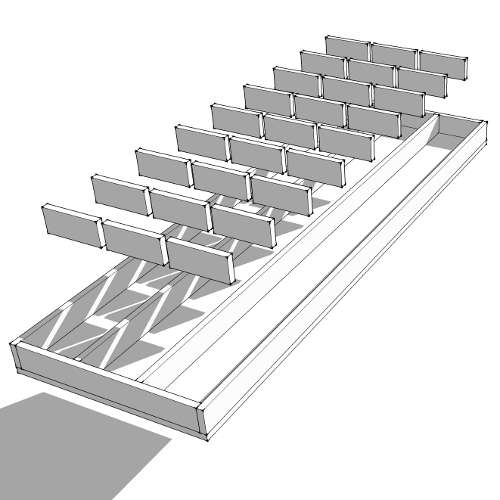

Lateral pieces to complete the grid.

The top layer.

Packing List:

List of Birch or MDO (Medium Density Overlay) pieces:

Top and Bottom Gantry Box (2)

Back Gantry Box (1)

Z-Axis Motor Mount (1)

Gantry Sides (2)

Y-Axis Rail Support Top and Bottom (2)

Y-Axis Rail Support Reinforcement (1)

Z/Y Plate (1)

Z-Axis Rail Supports (2)

Z-Axis Middle Supports (4, 2 long and 2 short)

Router/Spindle mounts (2)

Vacuum Mount Bottom (2 Parts for Suction Enclosure)

Vacuum Mount Top and Lead Screw Bearing Mount (1)

Z-Axis Lead Screw and Bearing Mount (1)

Y-Axis Chain Mount (4 - 1 long and 1 short and their respective clamps)

Y-Axis Motor Mount (1)

X-Axis Chain Mounts ((16 - Assemblies that are affixed to the table corners)

Hardware List:

Screws (#8) @ 1 1/4" (24)

Screws (1/4") @:

1" (16)

1-1/2" (77)

2" (40)

2-1/2" (4)

3" (14)

3-1/2" (4)

Screws (3/8") @:

2" (14)

2-1/2" (3)

3" (4)

Nuts:

#8 (18)

1/4" (46)

Cross dowels (114)

3/8" (28)

Eye Bolts (3)

Hose Clamps (3)

Washers:

For #8 Screws (16)

For 3/8":

Thin (16)

Large (22)

Small L-Brackets (For Anti-Backlash Nut) (2)

Bearings:

"V" Groove (3/8" Inside Diameter) (16)

Standard with 1/2" Inside Diameter

for Lead Screws (2)

1/4 Inside Diameter for X-axis Motor shaft Ends (2)

Couplings:

1/4" to 1/2" (1)

1/4" to 1/4" Rigid For X-Axis Shafts (2)

Steel Collars (1/2" Inside Diameter): (1)

Z-axis 10.5" lead screw (1)

Anti-backlash nut (1)

Drive Sprockets #25 9 teeth (3)

Idler Sprockets #25 25 Teeth (5)

Roller Chain #25 - Length show extra chain provided for convenience

8 Feet for X-Axis (2)

4 feet for Y-Axis (1)

Rods at 1/4" Diameter and 14" in Length (2)

Rails (aluminum angles drilled and cut to length) for the X, Y and Z axes

Electronics:

Stepper Motors at 425 oz-in NEMA 24 (3) - note NEMA 24 is a 60 mm Frame Size

Motor Drivers at 3.0 amps Max Rating and 1/64 Microstepping (3)

Power Supply 36v-8.8amp (1)

Power Supply 5v (2)

Breakout Board for

Computer Interface (1)

Optional Table

1/4 - 1.5" Screws (70)

Cross dowels (70)

Birch or MDO Pieces for:

Table Surface (4)

Ends (4)

Under Surface Structure (14)