Price Options Your Cart

2" Strip Brush per inch (Backordered)

2" Flexible Strip Brush (Great for making dust shoes for the router or spindle)Strip Brushes are really useful for aiding in the capture of dust and chips being ejected from the milling process on the CNC machine (the router or spindle cutting process). The dust shoe that can be found on most of our CNC machines uses this strip brush. The strip brush encloses the cutting area and the vacuum creating an area of negative pressure, so the chips or dust will be carried directly to the vacuum end. The strip brush also serves as a wall or barrier that the chips will hit rather than getting ejected into the air. Just make a groove the same width of the rubber side of the brush and glue the brush in.

Click here for more information on this product.

----

Instructions for the Z-Axis Assembly for the blackToe and blackFoot CNC Machine

Kits:

These instructions are a replacement for the video instructions on how to assemble

the Z-axis assembly and router/spindle mount. The updated Z-axis Assembly includes

mounts for varying sizes compatible with the Porter Cable 890, 7518, and a 2.2 kW

spindle with a dust shoe.

Parts

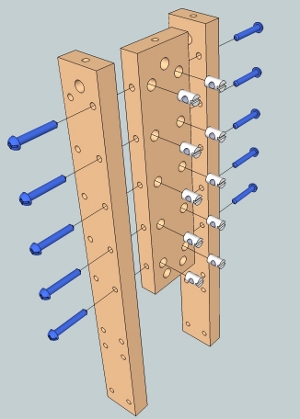

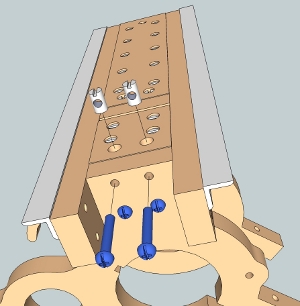

needed: Two long pieces on the sides (z-axis rail support side), one middle z-axis

rail support (long), 10 cross dowels and 10 screws at 1/4" x 1-1/2". The two z-axis

rail support sides will sandwich the wider piece in the middle. Leave the screws

loosened.

Parts

needed: Two long pieces on the sides (z-axis rail support side), one middle z-axis

rail support (long), 10 cross dowels and 10 screws at 1/4" x 1-1/2". The two z-axis

rail support sides will sandwich the wider piece in the middle. Leave the screws

loosened.

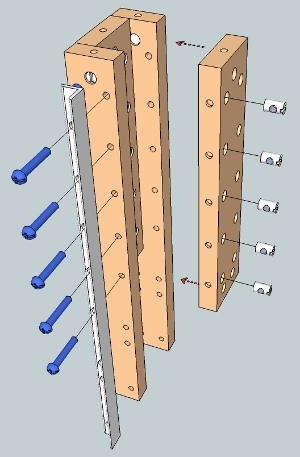

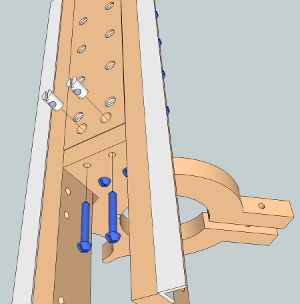

Parts needed:

Z-axis rail (the rail that matches the hole positions and orientation shown in the

illustration), one middle z-axis rail support (long), 5 cross dowels and 5 screws

at 1/4" x 1-1/2". With the rail positioned on the z-axis side rail support, add

the cross dowels and loosely fasten the screws into the cross dowels as shown in

the illustration.

Parts needed:

Z-axis rail (the rail that matches the hole positions and orientation shown in the

illustration), one middle z-axis rail support (long), 5 cross dowels and 5 screws

at 1/4" x 1-1/2". With the rail positioned on the z-axis side rail support, add

the cross dowels and loosely fasten the screws into the cross dowels as shown in

the illustration.

Parts needed:

Z-axis rail (the rail that matches the hole positions and orientation shown in the

illustration), one middle z-axis rail support (long), 5 cross dowels and 5 screws

at 1/4" x 1-1/2". Repeated step for other side of the z-axis. Leave the screws loosened.

For the spindle z-axis kit, the middle z-axis rail support will look very similar

to the part that is positioned just below. To properly identify this part, there

will be 9 holes on the face of the part.

Parts needed:

Z-axis rail (the rail that matches the hole positions and orientation shown in the

illustration), one middle z-axis rail support (long), 5 cross dowels and 5 screws

at 1/4" x 1-1/2". Repeated step for other side of the z-axis. Leave the screws loosened.

For the spindle z-axis kit, the middle z-axis rail support will look very similar

to the part that is positioned just below. To properly identify this part, there

will be 9 holes on the face of the part.

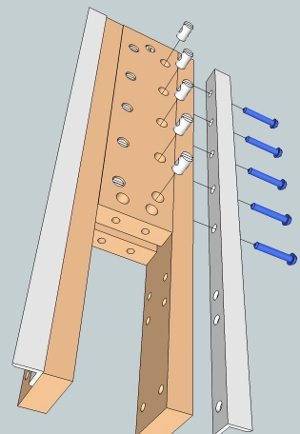

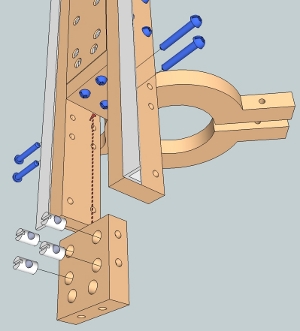

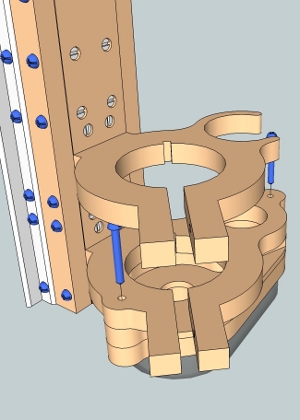

Parts needed: Top router mount, 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten

the top router mount with the two screws and cross dowels as shown in the illustration.

Parts needed: Top router mount, 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten

the top router mount with the two screws and cross dowels as shown in the illustration.

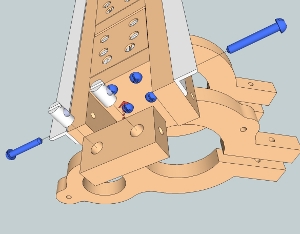

Parts needed: 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten the back portion

of the top router mount with the two screws and cross dowels as shown in the illustration.

Fully tighten these four screws as there will be no access to these screws in later

steps.

Parts needed: 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten the back portion

of the top router mount with the two screws and cross dowels as shown in the illustration.

Fully tighten these four screws as there will be no access to these screws in later

steps.

Parts needed: Middle rail support (medium length), 4 cross dowels and 4 screws at

1/4" x 1-1/2". Fasten the middle rail support along the back of the z-axis assembly

as shown in the illustration.

Parts needed: Middle rail support (medium length), 4 cross dowels and 4 screws at

1/4" x 1-1/2". Fasten the middle rail support along the back of the z-axis assembly

as shown in the illustration.

Parts needed: Middle rail support (medium length), 4 cross dowels and 4 screws at

1/4" x 1-1/2". Fasten the middle rail support along the front of the z-axis assembly

as shown in the illustration.

Parts needed: Middle rail support (medium length), 4 cross dowels and 4 screws at

1/4" x 1-1/2". Fasten the middle rail support along the front of the z-axis assembly

as shown in the illustration.

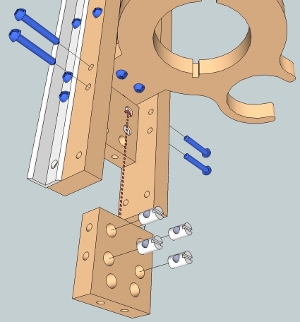

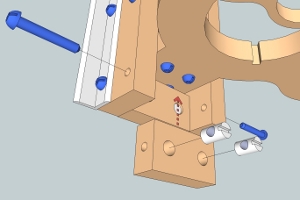

Parts needed: Bottom Router Mount, 2 cross dowels and 2 screws at 1/4" x 1-1/2".

Fasten the bottom router mount using the two front holes of the router mount as

shown inthe illustration.

Parts needed: Bottom Router Mount, 2 cross dowels and 2 screws at 1/4" x 1-1/2".

Fasten the bottom router mount using the two front holes of the router mount as

shown inthe illustration.

Parts needed: 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten the back portion

of the bottom router mount as shown in the illustration. Fully tighten these four

screws as there will be no access to these screws in later steps.

Parts needed: 2 cross dowels and 2 screws at 1/4" x 1-1/2". Fasten the back portion

of the bottom router mount as shown in the illustration. Fully tighten these four

screws as there will be no access to these screws in later steps.

Parts needed: Middle z-axis rail support (short), 2 cross dowels and 2 screws at

1/4" x 1-1/2". Position the middle z-axis rail support and fasten this part with

the screws and cross dowels as shown in the illustration for the back of the z-axis

assembly.

Parts needed: Middle z-axis rail support (short), 2 cross dowels and 2 screws at

1/4" x 1-1/2". Position the middle z-axis rail support and fasten this part with

the screws and cross dowels as shown in the illustration for the back of the z-axis

assembly.

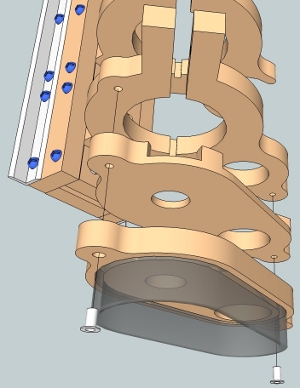

Parts needed: Middle z-axis rail support (short), 2 cross dowels and 2 screws at

1/4" x 1-1/2". Position the middle z-axis rail support and fasten this part with

the screws and cross dowels as shown in the illustration for the front of the z-axis

assembly. At this point of the assembly, lay the entire assembly on a flat table

oriented so that the rails are against the table. Tighten all of the loose screws

making sure that the assembly stays flat on the table. This will insure that the

rails are as parallel to each other as possible.

Parts needed: Middle z-axis rail support (short), 2 cross dowels and 2 screws at

1/4" x 1-1/2". Position the middle z-axis rail support and fasten this part with

the screws and cross dowels as shown in the illustration for the front of the z-axis

assembly. At this point of the assembly, lay the entire assembly on a flat table

oriented so that the rails are against the table. Tighten all of the loose screws

making sure that the assembly stays flat on the table. This will insure that the

rails are as parallel to each other as possible.

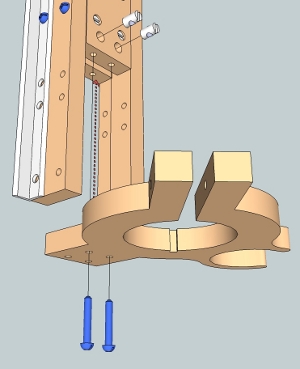

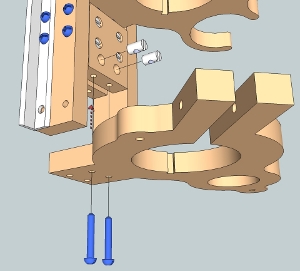

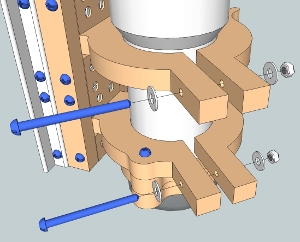

Parts needed: Top and bottom dust shoe and 2 nut inserts 1/4". Drive in the nut

inserts into the dust shoe that contains the brush using an allen wrench. Position

the dust shoe parts as shown in the illustration in preparation for the next step.

Parts needed: Top and bottom dust shoe and 2 nut inserts 1/4". Drive in the nut

inserts into the dust shoe that contains the brush using an allen wrench. Position

the dust shoe parts as shown in the illustration in preparation for the next step.

Parts needed: 2 screws at 1/4" x 2". Insert the screws at the top of the bottom

router mountand tighten the screws into the nut inserts. A short or angled screws

driver will be needed for one tightening one of these screws.

Parts needed: 2 screws at 1/4" x 2". Insert the screws at the top of the bottom

router mountand tighten the screws into the nut inserts. A short or angled screws

driver will be needed for one tightening one of these screws.

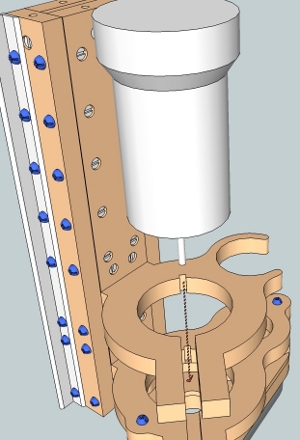

Parts needed: Router or spindle. This step can be done after the machine is completely

assembled. Slide the router or spindle through the openings of the router mounts.

If the routers contain dimples on the side, orient the router so that the dimple

is aligned with the notch in the router mount. Ant obstructions fastened to the

side of the router will need to be removed prior to installing the router to the

z-axis assembly.

Parts needed: Router or spindle. This step can be done after the machine is completely

assembled. Slide the router or spindle through the openings of the router mounts.

If the routers contain dimples on the side, orient the router so that the dimple

is aligned with the notch in the router mount. Ant obstructions fastened to the

side of the router will need to be removed prior to installing the router to the

z-axis assembly.

Parts needed: 2 screws at 1/4" x 3", 4 washers 1/4" and 2 nuts 1/4". These components

are used to firmly squeeze the router mounts rount the housing of the router. Gently

tighten the screws until the router is secure.

Parts needed: 2 screws at 1/4" x 3", 4 washers 1/4" and 2 nuts 1/4". These components

are used to firmly squeeze the router mounts rount the housing of the router. Gently

tighten the screws until the router is secure.