BuildYourCNC

1/4" ER11 Collet for Spindles

1/4" ER11 Collet for Spindles

Couldn't load pickup availability

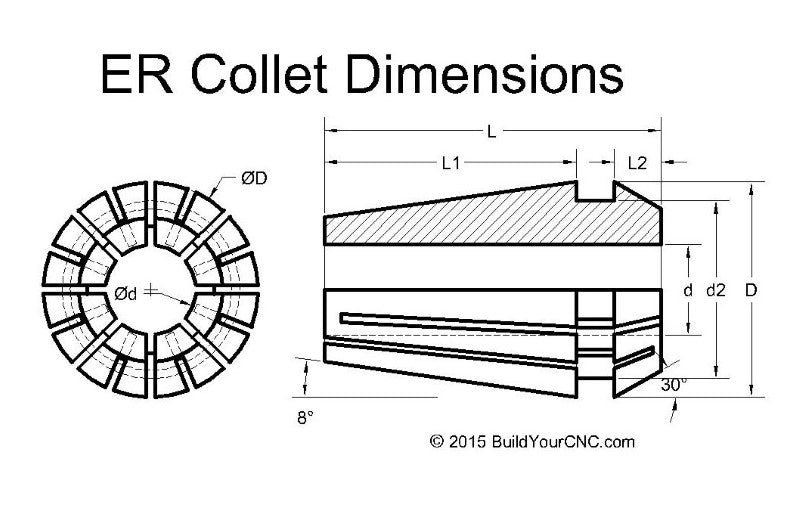

This is the part of the spindle that will hold and grip the end mill at the spinning part of the spindle. This is a collet for smaller spindles with the ER-11 specification. This collet will accept tools with a 1/4" (6.35mm) shank. This collet has a high precision TIR (Total Indicated Runout) of 0.0002". The bore measures 1/4" .25 inch (6.35 mm) to hold end mills that have a 1/4" shank. The shank of an end mill is the smooth part of the end mill that is inserted into the collet of the end mill. General dimensions for ER-11 collets: D (Outside Diameter): 0.453 inches (11.5062 mm) L (Overall Length): 0.709 inches (18.0086 mm) L1 (Front Tapered Length): 0.531 inches (13.4874 mm) L2 (Rear Tapered Length): 0.098 inches (2.4892 mm) This Collet Bore Diameter (d): .25 inches (6.35 mm)

Share

Questions & Answers

Have a Question?

-

Can bits with shank length of 1" be used in the 1/8" ER20 collet?

If this endmill/bit has a shaft of 1", plus the cut length the ER-20 collets we provide will work without any issues. If the shank goes into the 1/8" ER20-collet at least .773 (safety margin), it will work without any problems. (This is only for the 1/8" ER20-collet)