Diagnosing and Fixing a Non-working Axis

Share

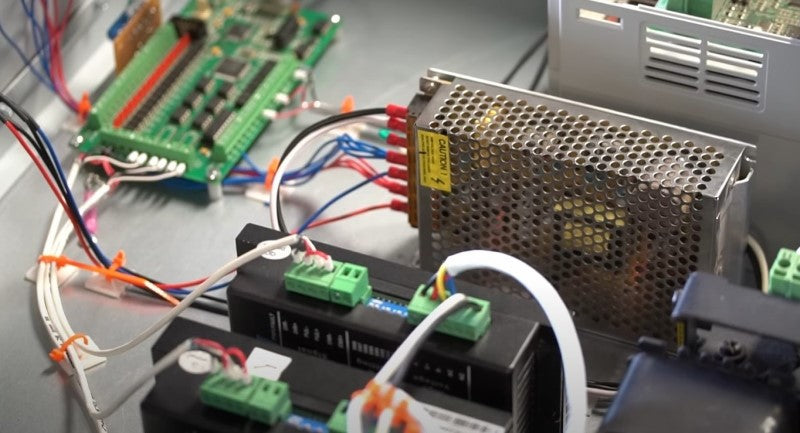

Decoding the X-Axis Mystery, or any axis for that matter: A Step-by-Step Guide to CNC Electronics Troubleshooting Working with CNC (Computer Numerical Control) electronics is akin to assembling a complex puzzle, where each piece has a critical role in creating a functional masterpiece. Let's dive into the specifics without losing you in jargon. A customer sent me an array of electronics from his CNC machine for cabinet placement and rewiring. In layman's terms, a cabinet is like a control center where all the components live. Here’s a detailed list of what was included:  Transformer: This is the powerhouse that takes in 220 volts and then dishes out four separate channels of 70 volts each. It's essentially the heart of the operation, responsible for distributing the right amount of electricity to different components. 24-Volt Power Supply: Think of this as the blood supply to the CNC’s sensory organs, the proximity switches. These switches detect objects in close range, much like our sense of touch. VFD (Variable Frequency Drive): This is the brain's command center for the machine's spindle, which is a motor responsible for spinning the cutting tool. It's like the throttle in a car, controlling how fast or slow you go. Drivers: Three in total, plus one extra as a backup, particularly for the X-axis. These are the muscles, making the machine move in different directions (X, Y, and Z). Each driver can handle 18 to 80 volts of alternating current (AC) or 36 to 100 volts of direct current (DC).

Transformer: This is the powerhouse that takes in 220 volts and then dishes out four separate channels of 70 volts each. It's essentially the heart of the operation, responsible for distributing the right amount of electricity to different components. 24-Volt Power Supply: Think of this as the blood supply to the CNC’s sensory organs, the proximity switches. These switches detect objects in close range, much like our sense of touch. VFD (Variable Frequency Drive): This is the brain's command center for the machine's spindle, which is a motor responsible for spinning the cutting tool. It's like the throttle in a car, controlling how fast or slow you go. Drivers: Three in total, plus one extra as a backup, particularly for the X-axis. These are the muscles, making the machine move in different directions (X, Y, and Z). Each driver can handle 18 to 80 volts of alternating current (AC) or 36 to 100 volts of direct current (DC).  Contactor: This is a specialized switch that’s activated by a simple push-button, working as the machine's "on/off" mechanism.

Contactor: This is a specialized switch that’s activated by a simple push-button, working as the machine's "on/off" mechanism.  Mach 3 USB Controller with 200-kHz Frequency: Imagine this as the nervous system. It has 16 input channels and 8 output channels, allowing it to communicate with various parts of the CNC machine. It also controls the speed of the spindle through a PWM (Pulse Width Modulation) signal. It can even sense the spindle's speed using S+ and S- terminals, although this feature is not currently in use. This controller is specifically designed for three axes (X, Y, Z) because it lacks opto-couplers for a fourth axis. Opto-couplers are like safety guards, ensuring electrical isolation between different parts of the machine. The Assembly and Diagnostic Process Step 1: I started by turning on the contactor and measuring its output voltage to ensure it matched its input voltage. Step 2: I connected the transformer to the contactor and verified that each pair of its 70-volt outputs was functioning correctly. Step 3: Each driver was then connected to the transformer. All three drivers showed a green light, indicating they were in good health. I suspected the issue with the X-axis driver might be a loose connection or something minor and fixable. Additional Details Cabling: The customer chose to use his own shielded cables, which are great for reducing electrical noise. My connectors have screw terminals for easy cable attachment. Push Button: It’s equipped with an LED indicator and requires a 24-volt input to light up. Contactor Specs: The contactor was initially rated for 50 Hz, which is not compatible with the 60 Hz standard in the U.S., hence it was replaced. When engaged, it pulled in a coil with a resistance of 1K ohms, drawing only 0.2 amps of current. Finally, I tackled the issue of the non-responsive X-axis. After connecting all necessary wires to the Mach 3 USB controller and aligning the step and direction signals to each driver, I initiated a test run. First, I tried to make the X-axis motor move. That's the one that goes left and right. But guess what? It didn't budge! Not even a wiggle. But something interesting happened: when I pressed the arrow keys on my computer, numbers changed on the screen, and a tiny light (we call it an LED) on a box called a controller started blinking. This controller is like the brain of the machine, telling the motors what to do. So, the blinking light and changing numbers are like the machine's way of saying, "Hey, I hear you, but I can't move right now!"

Mach 3 USB Controller with 200-kHz Frequency: Imagine this as the nervous system. It has 16 input channels and 8 output channels, allowing it to communicate with various parts of the CNC machine. It also controls the speed of the spindle through a PWM (Pulse Width Modulation) signal. It can even sense the spindle's speed using S+ and S- terminals, although this feature is not currently in use. This controller is specifically designed for three axes (X, Y, Z) because it lacks opto-couplers for a fourth axis. Opto-couplers are like safety guards, ensuring electrical isolation between different parts of the machine. The Assembly and Diagnostic Process Step 1: I started by turning on the contactor and measuring its output voltage to ensure it matched its input voltage. Step 2: I connected the transformer to the contactor and verified that each pair of its 70-volt outputs was functioning correctly. Step 3: Each driver was then connected to the transformer. All three drivers showed a green light, indicating they were in good health. I suspected the issue with the X-axis driver might be a loose connection or something minor and fixable. Additional Details Cabling: The customer chose to use his own shielded cables, which are great for reducing electrical noise. My connectors have screw terminals for easy cable attachment. Push Button: It’s equipped with an LED indicator and requires a 24-volt input to light up. Contactor Specs: The contactor was initially rated for 50 Hz, which is not compatible with the 60 Hz standard in the U.S., hence it was replaced. When engaged, it pulled in a coil with a resistance of 1K ohms, drawing only 0.2 amps of current. Finally, I tackled the issue of the non-responsive X-axis. After connecting all necessary wires to the Mach 3 USB controller and aligning the step and direction signals to each driver, I initiated a test run. First, I tried to make the X-axis motor move. That's the one that goes left and right. But guess what? It didn't budge! Not even a wiggle. But something interesting happened: when I pressed the arrow keys on my computer, numbers changed on the screen, and a tiny light (we call it an LED) on a box called a controller started blinking. This controller is like the brain of the machine, telling the motors what to do. So, the blinking light and changing numbers are like the machine's way of saying, "Hey, I hear you, but I can't move right now!"  Next, I tried the Y-axis, which moves the machine front and back. And guess what? It worked like a charm! Then I tried the Z-axis, the one that moves up and down. It also worked perfectly. So now I had a puzzle to solve: why wasn't the X-axis moving? Here's where I turned into a machine detective. The problem could be with many things: the X-axis motor itself, a device called a "driver" that helps the motor move, the cables connecting them, or even the power supply that gives them energy. It could also be the controller, the brain of the machine. I didn't need any fancy gadgets to figure this out. I used stuff I already had in my toolbox and some simple tests. First, I looked at the X-axis driver (it helps the motor know how fast or slow to move). It had a green light on it, which usually means it's getting the right amount of power. To double-check, I used a tool called a multimeter to measure the electricity coming from the power supply to the driver. To get even more clues, I switched some wires and connectors around with the Y-axis, which was working fine. If the Y-axis motor moved when hooked up to the X-axis driver, then I'd know the driver was okay.

Next, I tried the Y-axis, which moves the machine front and back. And guess what? It worked like a charm! Then I tried the Z-axis, the one that moves up and down. It also worked perfectly. So now I had a puzzle to solve: why wasn't the X-axis moving? Here's where I turned into a machine detective. The problem could be with many things: the X-axis motor itself, a device called a "driver" that helps the motor move, the cables connecting them, or even the power supply that gives them energy. It could also be the controller, the brain of the machine. I didn't need any fancy gadgets to figure this out. I used stuff I already had in my toolbox and some simple tests. First, I looked at the X-axis driver (it helps the motor know how fast or slow to move). It had a green light on it, which usually means it's getting the right amount of power. To double-check, I used a tool called a multimeter to measure the electricity coming from the power supply to the driver. To get even more clues, I switched some wires and connectors around with the Y-axis, which was working fine. If the Y-axis motor moved when hooked up to the X-axis driver, then I'd know the driver was okay.  Next, I connected the X-axis motor to the Y-axis driver and used buttons on my computer to try to make it move. If it moved, then the motor was also okay. Then, I switched some more wires around to see if the problem was with the signals coming from the controller.

Next, I connected the X-axis motor to the Y-axis driver and used buttons on my computer to try to make it move. If it moved, then the motor was also okay. Then, I switched some more wires around to see if the problem was with the signals coming from the controller.

If the motor moved after all this switching, then it would mean that the driver and the motor were both okay, and I would need to look at the controller. The controller has tiny chips inside it called "optocouplers" that help protect it. They make sure that the commands from the controller get to the motors safely. I found out that one of these optocouplers was broken and replaced it. That fixed the problem! Finally, I checked some special sensors called "proximity switches" that the machine uses to know if something is close to it. I made sure they were working by using different colored wires: white for the signal, black for the ground (like an earth wire), and red for power. I tested each one to make sure a light on the board switched on and off, which would mean they're working right. And there you have it! We solved the mystery, just like detectives, but for machines!

If the motor moved after all this switching, then it would mean that the driver and the motor were both okay, and I would need to look at the controller. The controller has tiny chips inside it called "optocouplers" that help protect it. They make sure that the commands from the controller get to the motors safely. I found out that one of these optocouplers was broken and replaced it. That fixed the problem! Finally, I checked some special sensors called "proximity switches" that the machine uses to know if something is close to it. I made sure they were working by using different colored wires: white for the signal, black for the ground (like an earth wire), and red for power. I tested each one to make sure a light on the board switched on and off, which would mean they're working right. And there you have it! We solved the mystery, just like detectives, but for machines!

Transformer: This is the powerhouse that takes in 220 volts and then dishes out four separate channels of 70 volts each. It's essentially the heart of the operation, responsible for distributing the right amount of electricity to different components. 24-Volt Power Supply: Think of this as the blood supply to the CNC’s sensory organs, the proximity switches. These switches detect objects in close range, much like our sense of touch. VFD (Variable Frequency Drive): This is the brain's command center for the machine's spindle, which is a motor responsible for spinning the cutting tool. It's like the throttle in a car, controlling how fast or slow you go. Drivers: Three in total, plus one extra as a backup, particularly for the X-axis. These are the muscles, making the machine move in different directions (X, Y, and Z). Each driver can handle 18 to 80 volts of alternating current (AC) or 36 to 100 volts of direct current (DC).

Transformer: This is the powerhouse that takes in 220 volts and then dishes out four separate channels of 70 volts each. It's essentially the heart of the operation, responsible for distributing the right amount of electricity to different components. 24-Volt Power Supply: Think of this as the blood supply to the CNC’s sensory organs, the proximity switches. These switches detect objects in close range, much like our sense of touch. VFD (Variable Frequency Drive): This is the brain's command center for the machine's spindle, which is a motor responsible for spinning the cutting tool. It's like the throttle in a car, controlling how fast or slow you go. Drivers: Three in total, plus one extra as a backup, particularly for the X-axis. These are the muscles, making the machine move in different directions (X, Y, and Z). Each driver can handle 18 to 80 volts of alternating current (AC) or 36 to 100 volts of direct current (DC).  Contactor: This is a specialized switch that’s activated by a simple push-button, working as the machine's "on/off" mechanism.

Contactor: This is a specialized switch that’s activated by a simple push-button, working as the machine's "on/off" mechanism.  Mach 3 USB Controller with 200-kHz Frequency: Imagine this as the nervous system. It has 16 input channels and 8 output channels, allowing it to communicate with various parts of the CNC machine. It also controls the speed of the spindle through a PWM (Pulse Width Modulation) signal. It can even sense the spindle's speed using S+ and S- terminals, although this feature is not currently in use. This controller is specifically designed for three axes (X, Y, Z) because it lacks opto-couplers for a fourth axis. Opto-couplers are like safety guards, ensuring electrical isolation between different parts of the machine. The Assembly and Diagnostic Process Step 1: I started by turning on the contactor and measuring its output voltage to ensure it matched its input voltage. Step 2: I connected the transformer to the contactor and verified that each pair of its 70-volt outputs was functioning correctly. Step 3: Each driver was then connected to the transformer. All three drivers showed a green light, indicating they were in good health. I suspected the issue with the X-axis driver might be a loose connection or something minor and fixable. Additional Details Cabling: The customer chose to use his own shielded cables, which are great for reducing electrical noise. My connectors have screw terminals for easy cable attachment. Push Button: It’s equipped with an LED indicator and requires a 24-volt input to light up. Contactor Specs: The contactor was initially rated for 50 Hz, which is not compatible with the 60 Hz standard in the U.S., hence it was replaced. When engaged, it pulled in a coil with a resistance of 1K ohms, drawing only 0.2 amps of current. Finally, I tackled the issue of the non-responsive X-axis. After connecting all necessary wires to the Mach 3 USB controller and aligning the step and direction signals to each driver, I initiated a test run. First, I tried to make the X-axis motor move. That's the one that goes left and right. But guess what? It didn't budge! Not even a wiggle. But something interesting happened: when I pressed the arrow keys on my computer, numbers changed on the screen, and a tiny light (we call it an LED) on a box called a controller started blinking. This controller is like the brain of the machine, telling the motors what to do. So, the blinking light and changing numbers are like the machine's way of saying, "Hey, I hear you, but I can't move right now!"

Mach 3 USB Controller with 200-kHz Frequency: Imagine this as the nervous system. It has 16 input channels and 8 output channels, allowing it to communicate with various parts of the CNC machine. It also controls the speed of the spindle through a PWM (Pulse Width Modulation) signal. It can even sense the spindle's speed using S+ and S- terminals, although this feature is not currently in use. This controller is specifically designed for three axes (X, Y, Z) because it lacks opto-couplers for a fourth axis. Opto-couplers are like safety guards, ensuring electrical isolation between different parts of the machine. The Assembly and Diagnostic Process Step 1: I started by turning on the contactor and measuring its output voltage to ensure it matched its input voltage. Step 2: I connected the transformer to the contactor and verified that each pair of its 70-volt outputs was functioning correctly. Step 3: Each driver was then connected to the transformer. All three drivers showed a green light, indicating they were in good health. I suspected the issue with the X-axis driver might be a loose connection or something minor and fixable. Additional Details Cabling: The customer chose to use his own shielded cables, which are great for reducing electrical noise. My connectors have screw terminals for easy cable attachment. Push Button: It’s equipped with an LED indicator and requires a 24-volt input to light up. Contactor Specs: The contactor was initially rated for 50 Hz, which is not compatible with the 60 Hz standard in the U.S., hence it was replaced. When engaged, it pulled in a coil with a resistance of 1K ohms, drawing only 0.2 amps of current. Finally, I tackled the issue of the non-responsive X-axis. After connecting all necessary wires to the Mach 3 USB controller and aligning the step and direction signals to each driver, I initiated a test run. First, I tried to make the X-axis motor move. That's the one that goes left and right. But guess what? It didn't budge! Not even a wiggle. But something interesting happened: when I pressed the arrow keys on my computer, numbers changed on the screen, and a tiny light (we call it an LED) on a box called a controller started blinking. This controller is like the brain of the machine, telling the motors what to do. So, the blinking light and changing numbers are like the machine's way of saying, "Hey, I hear you, but I can't move right now!"  Next, I tried the Y-axis, which moves the machine front and back. And guess what? It worked like a charm! Then I tried the Z-axis, the one that moves up and down. It also worked perfectly. So now I had a puzzle to solve: why wasn't the X-axis moving? Here's where I turned into a machine detective. The problem could be with many things: the X-axis motor itself, a device called a "driver" that helps the motor move, the cables connecting them, or even the power supply that gives them energy. It could also be the controller, the brain of the machine. I didn't need any fancy gadgets to figure this out. I used stuff I already had in my toolbox and some simple tests. First, I looked at the X-axis driver (it helps the motor know how fast or slow to move). It had a green light on it, which usually means it's getting the right amount of power. To double-check, I used a tool called a multimeter to measure the electricity coming from the power supply to the driver. To get even more clues, I switched some wires and connectors around with the Y-axis, which was working fine. If the Y-axis motor moved when hooked up to the X-axis driver, then I'd know the driver was okay.

Next, I tried the Y-axis, which moves the machine front and back. And guess what? It worked like a charm! Then I tried the Z-axis, the one that moves up and down. It also worked perfectly. So now I had a puzzle to solve: why wasn't the X-axis moving? Here's where I turned into a machine detective. The problem could be with many things: the X-axis motor itself, a device called a "driver" that helps the motor move, the cables connecting them, or even the power supply that gives them energy. It could also be the controller, the brain of the machine. I didn't need any fancy gadgets to figure this out. I used stuff I already had in my toolbox and some simple tests. First, I looked at the X-axis driver (it helps the motor know how fast or slow to move). It had a green light on it, which usually means it's getting the right amount of power. To double-check, I used a tool called a multimeter to measure the electricity coming from the power supply to the driver. To get even more clues, I switched some wires and connectors around with the Y-axis, which was working fine. If the Y-axis motor moved when hooked up to the X-axis driver, then I'd know the driver was okay.  Next, I connected the X-axis motor to the Y-axis driver and used buttons on my computer to try to make it move. If it moved, then the motor was also okay. Then, I switched some more wires around to see if the problem was with the signals coming from the controller.

Next, I connected the X-axis motor to the Y-axis driver and used buttons on my computer to try to make it move. If it moved, then the motor was also okay. Then, I switched some more wires around to see if the problem was with the signals coming from the controller.

If the motor moved after all this switching, then it would mean that the driver and the motor were both okay, and I would need to look at the controller. The controller has tiny chips inside it called "optocouplers" that help protect it. They make sure that the commands from the controller get to the motors safely. I found out that one of these optocouplers was broken and replaced it. That fixed the problem! Finally, I checked some special sensors called "proximity switches" that the machine uses to know if something is close to it. I made sure they were working by using different colored wires: white for the signal, black for the ground (like an earth wire), and red for power. I tested each one to make sure a light on the board switched on and off, which would mean they're working right. And there you have it! We solved the mystery, just like detectives, but for machines!

If the motor moved after all this switching, then it would mean that the driver and the motor were both okay, and I would need to look at the controller. The controller has tiny chips inside it called "optocouplers" that help protect it. They make sure that the commands from the controller get to the motors safely. I found out that one of these optocouplers was broken and replaced it. That fixed the problem! Finally, I checked some special sensors called "proximity switches" that the machine uses to know if something is close to it. I made sure they were working by using different colored wires: white for the signal, black for the ground (like an earth wire), and red for power. I tested each one to make sure a light on the board switched on and off, which would mean they're working right. And there you have it! We solved the mystery, just like detectives, but for machines!