Cutting Aluminum Fail Using a Cheap End Mill

Share

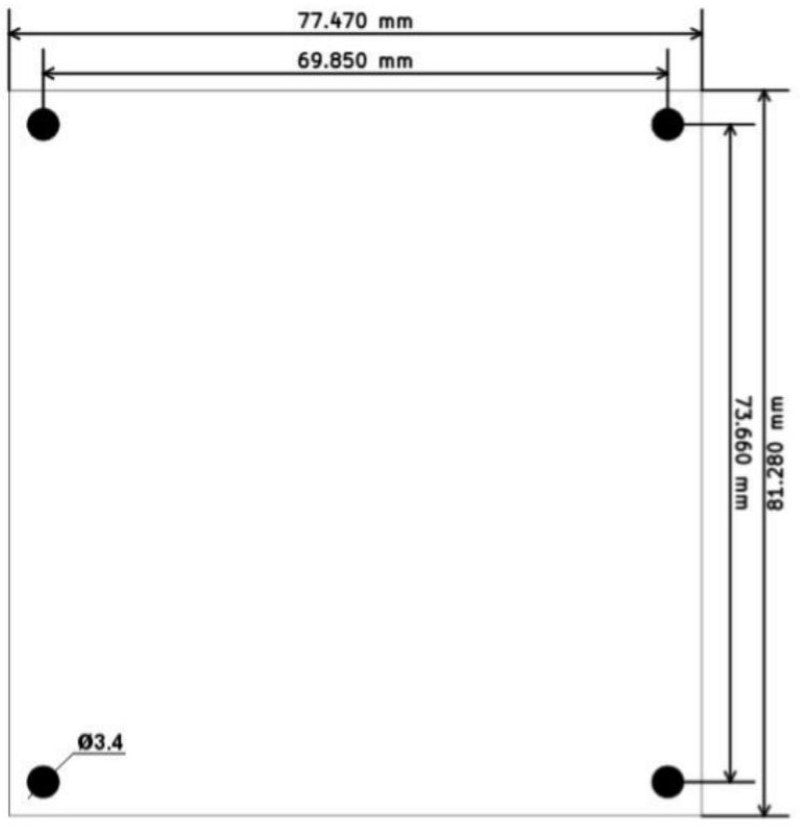

Video: Cutting Aluminum With a Cheap End Mill This job could have easily been done using an aluminum extruded round tube stock by cutting the stock at a specified length then refining the stock in a lathe, but the customer was under a time crunch so we offered our services to make an attempt to mill a ring out of a solid block. The CAMing of the part is pretty simple. We create the geometry to provide machining operations for the machine. The ring is composed of just two circles: one for the outside and inside diameter. I also wanted to create the geometry for the block so that we can find the correct origin on the aluminum block so the ring would be milled generally in the center of the block. The thickness of the ring is determined by the stock thickness, then a machining operation is applied to the circles, the outside is an outside profile so the end mill will mill along the outside of the line creating an outer wall. The inside will mill along the inside of the line creating an inner wall. During the creation of the milling operations, I didn’t take care to adjust the depth per pass. I left the depth per pass at the default values that I use for plexiglass that is a bit deeper than a quarter inch. The value I should have started with is .1 inches, that is if I was using an Onsrud end mill, rather than a general purpose (cheap) end mill. This is a general purpose end mill so I’m never quite sure what to expect. I always provide a roughing and finishing pass to correct any issues that may be caused by load on the bit while machining. Finally, I created the holding tabs so the ring would be in place during all of the machining operations. We’ve cut aluminum before, but using a quarter inch end mill, cutting into a quarter inch aluminum stock, our quarter inch end mills have a 1 1/8” flute length, not quite enough to penetrate the entire stock. Quite a bit of shank from the end mill would have rubbed along the top of the aluminum causing a great amount of heat, so we couldn’t use it. We had to use the ½” end mill which has a 2 inch flute length. Heat is the main attribute of machining that you want to eliminate, especially with aluminum since it has a low melting point. When you start machining aluminum, the bit can get too hot and start melting the chips. When the aluminum starts melting, the chips can get sticky and fuse into the flutes of the end mill, rendering it useless and it will eventually get stuck. In this attempt I reduced the depth per pass to .1 inches instead of the default that I was using before. I’m using .1 inches because our quarter inch end mills can use this in .05 and now we’re using a half inch end mill so I’m doubling depth per pass. I should be able to go even deeper with a better end mill, but we’re using a cheap end mill. I kept the feed rate as fast as possible. I want to maintain the feed rate because I want to make sure the end mill is always digging into cooler material, so the material always acts as sort of a coolant. The faster you go around the material, the cooler the material will be. This seems counterintuitive but this is actually the way dry cutting is done. You go through the material faster. You might do a shallower depth per pass. Even though we do maintain the speed, it seemed like the end mill was still getting very hot. I really should have selected a higher quality end mill. One that exhibits the flute geometry specifically appropriate for cutting aluminum. In this third attempt, the end mill was still having a hard time during some deep passes and I believe this is attributed to the heat build-up. The chips were fusing into the flutes of the end mill. Another condition that we saw that could be building up heat is that the end mill was actually stopping at another portion of the circle, and it was stopping at multiple points. This is a condition called a lead-in. The lead-in was at a 10 degree angle, so when you reduce the depth per pass, the lead angle is shorted. So we reduced the angle to about 1 degree so it will have a longer lead in so when it comes around it will start to lead in and then continue on to reduce some heat as well. In our last attempt, which wasn’t entirely successful, we were able to cut out the entire ring, but we had to go to a .025 which is an incredibly small depth per pass. Our quarter inch end mill can surpass this, but again this was because we weren’t using a higher quality end mill. We added cutting fluid so we could get less heat. One of the problems was the machine was starting to vibrate, so we ended that process without doing the finishing passes, so our wall thickness was not consistent with what the customer needed. I would like to attempt cutting aluminum again with a better end mill. We’re going to get a single flute, half inch Onsrud bit and we will demonstrate cutting an aluminum block with the same dimensions.