Instructions

1

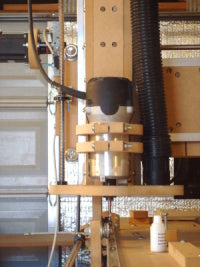

Blacktoe Assembly Videos: Here you will find the videos needed to assemble the blacktoe CNC machine. These videos will provide the necessary information for the entire assembly, including the table which does not come with the kit. In each step, I describe the tools needed and the hardware and parts that are required for the assembly. The first video will cover beginning of the z-axis assembly. The y-axis assembly will be covered thereafter, and finally, the gantry and table will finish the assembly videos. For supplemental videos on how to attach the roller chain components, go here.