1

/

of

4

BuildYourCNC

1'x3' (12"x36") CNC Router Assembled Machine

1'x3' (12"x36") CNC Router Assembled Machine

Regular price

$2,149.00 USD

Regular price

Sale price

$2,149.00 USD

Unit price

/

per

Couldn't load pickup availability

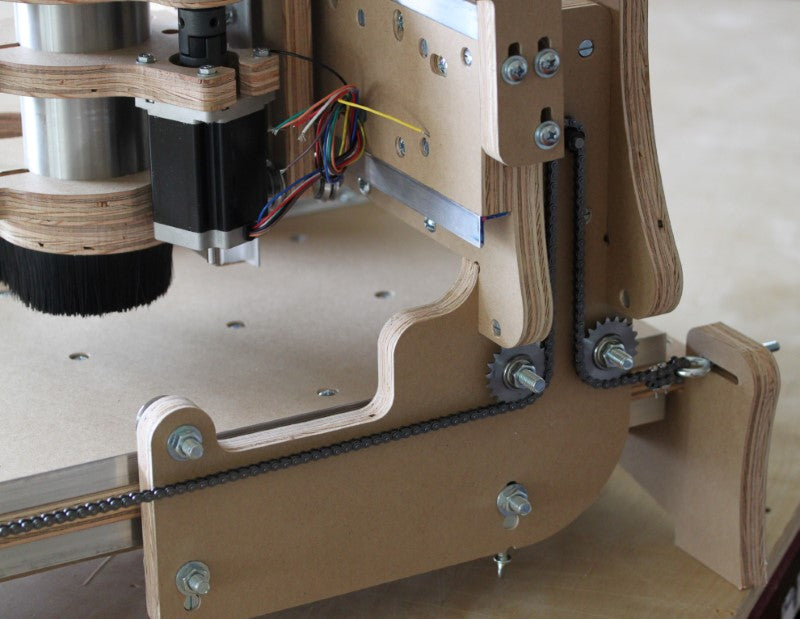

The blueChick v4.2 fully assembled CNC machine is a desktop sized CNC machine that has a working area of 12"x36"x3" (X, Y and Z travel distances. The blueChick is perfect for small routing jobs and is designed to use the Porter Cable 892 router, or our 1.5kW spindle. The blueChick is a fully assembled CNC machine capable of routing an area of 12"x36" with a total of 3" of z-axis travel. The version 4.2 was developed to provide an alternative drive method, locate the x-axis motor in a more appropriate location, increase the gantry structure and reduce the overall height of the machine. Additionally, the router selected for this machine is the Porter Cable 892 series of routers. We have several options for this machine. You will be able to purchase the fully assembled machine which will include a 2 week lead time. You supply the computer, cable/wires, and router. If you wish to purchase our Spindle, we include a price option for that as well. With the base price, the electronics will not come assembled. If putting electronics is not your thing, we have the electronics and computer all put together for you with the redLeaf or redSprout option. The redLeaf includes a larger form factor with adequate space for an additional 4th axis. We will build you a custom computer with all electronics pre-wired. It also includes a copy of Windows 7 with a free trial version of Mach3 software pre-installed. With this option, all you need to provide is the Spindle or Router, and you are ready to go out of the box. If you wish to have the electronics and motors mounted and ready to go but you don't need the computer, we have the redFly option in which we will mount the motors and drivers onto a custom built wood box. During the design of this machine, it was important to maintain the most rigidity possible, and the selection of the router was key in this decision. The Porter Cable has a consistently dimensioned cylindrical motor housing which contributes to the structural integrity of the z-axis assembly. This is in contrast to the Bosch routers which has a complex housing form which is challenging for which to provide a mount. This is evident on the version 3.0, where there is only a single mount for the Bosch and two mounts for the Porter Cable. Two mounts are always better than one as the router will be much sturdier while routing. The x-axis motor is in the new reinforced gantry structure (not under the table). The gantry structure is more in line with the blackToe and blackFoot CNC machines to provide an immense amount of structural rigidity to resist torsion. Torsion along the gantry happens when there is load on the router's bit as the machine travels along the x-axis. With the motor located within the gantry, the table has an unlimited length potential. The z-axis motor is re-oriented to be located next to the router as opposed to the top of the z-axis assembly. This reduces the overall height envelope of the CNC machine, so this machine can sit underneath cabinetry and other areas that have a similar height restriction. The chief difference from the version 3.0 blueChick CNC machine and this 4.2 version is the main drive mechanism. Roller chain was selected for this version to provide more robustness and ease of alignment. There is also a very interesting industrial appearance that comes with this type of mechanism. As with all machines, care should be taken with respect to fingers and other body parts getting into the parts of this mechanism. Many of the parts that relate to alignment of the drive mechanics (roller chain and lead screw) are made to be adjustable. Most importantly, the chain can be tightened from either end of each axis. This makes it very easy to square the x-axis with respect to the y-axis. The height of the y-axis can be adjusted vertically to make sure the chain is perfectly horizontal. The Lead screw can be aligned in both x and y direction so the lead screw can be oriented vertically. blueChick version 4.2 CNC Machine Features:

- Routing Area 12"x36"x3"

- Total envelope of the machine 24"x51"x22"

- Structural Material: MDO (Medium Density Overlay)

- Drive Method: X and Y axes: Roller Chain, Z axis: ACME Precision Lead screw and Anti-Backlash Nut (1/2"-10TPI @ 5 Starts - 2 turns per inch)

- Drive sprockets - 9 teeth #25, pitch 1/4" (2.25" pitch circumference)

- Rails: Aluminum 6061-T6. T6 Tempered for increased strength, good workability and high resistance to corrosion. Brinell Hardness: 95, Rockwell A Hardness: 40, Rockwell B Hardness: 60, Modulus of Elasticity: 10000 ksi (10000000 psi).

- Rail bearings: Hardened Steel Dual Race V-Groove bearings (RM2), also known as "W" profile bearings.

Share

Questions & Answers

Have a Question?

-

i have Artcam 2013 for an General Inc. Icarver 40913. My computer crash with the Licenses from Delcam i would like to know how to get the licenses.

If you purchased the ArtCAM from us, please send an email to us at customerservice@buildyourcnc.com with the name used with making the order and we will contact the developer to send you the license.