1

/

of

1

BuildYourCNC

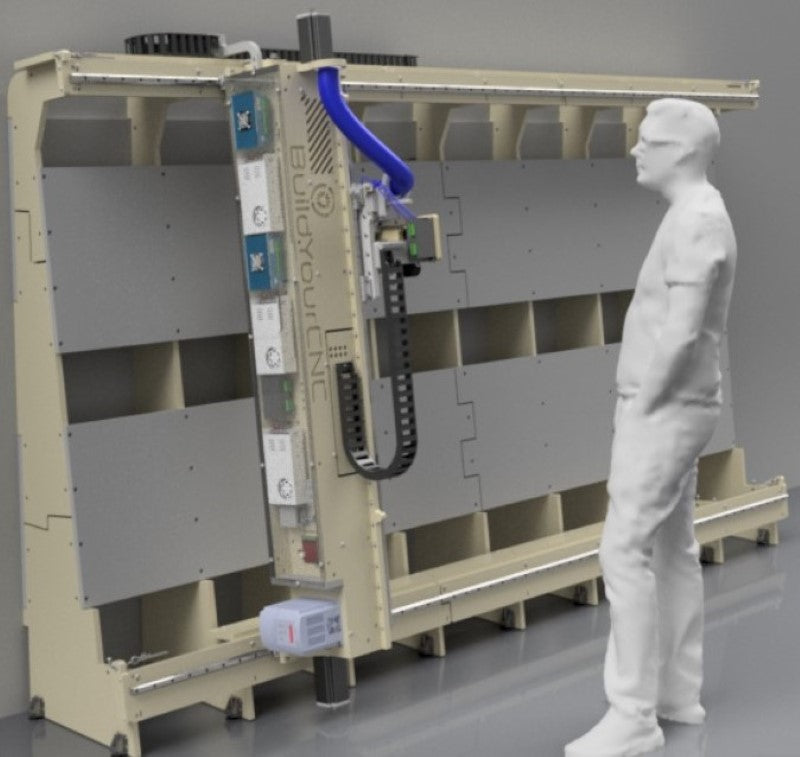

greenLean v2 Large CNC Router Plans

greenLean v2 Large CNC Router Plans

Regular price

$590.00 USD

Regular price

Sale price

$590.00 USD

Unit price

/

per

Couldn't load pickup availability

Elevate your woodworking and crafting capabilities with our top-tier DIY CNC Router Plans for the greenLean v2. Designed specifically for enthusiasts and professionals who are tight on space, these detailed 24"x36" digital plans are a must-have for anyone looking to build their own large-format, vertical CNC machine. Perfect for creating custom cabinets, intricate signs, and unique projects, the greenLean v2 allows even small workshops or home-based businesses to harness the power of CNC technology without compromising on space. Premium DIY CNC Router Plans: Space-Saving Vertical Design 24"x36" Digital Download Key Features of Our greenLean v2 CNC Router Plans: Revolutionary Vertical CNC Design The greenLean v2 is a groundbreaking wall-mounted CNC machine that offers a generous 4'x8' cutting area with a surprisingly small footprint. This innovative design is perfect for small shops or home-based businesses where space is at a premium. By mounting vertically against a wall, it frees up valuable floor space without sacrificing functionality. Complete Machine Structure Unlike traditional CNC machines, the greenLean v2 is designed as a complete unit—you don't need to build your own table. Our plans provide detailed instructions for constructing the entire structure, including the wall-mounted frame and adjustable supports, ensuring stability and precision in your projects. Detailed Bill of Materials (BOM) Our comprehensive BOM lists all necessary components and materials, making procurement straightforward and efficient. From mechanical parts to electronics, you'll have a clear roadmap of what's needed to bring your CNC machine to life. Precise Cutting and Drilling Templates We provide full-scale (1:1) templates for all parts requiring cutting and drilling, serving as accurate guides for precision work. These templates reduce the margin of error and simplify the building process, even for those new to CNC machine construction. Step-by-Step Assembly and Wiring Instructions Our plans include in-depth instructions for both assembly and wiring, ensuring a smooth building process from start to finish. With clear illustrations and expert guidance, you'll navigate the complexities of CNC construction with confidence. Expert Tips and Techniques Benefit from professional tips and techniques alongside basic instructions to enhance your building experience and machine performance. These insights are designed to help you avoid common pitfalls and optimize your CNC machine for peak efficiency. High-Performance CNC Spindle Integration These plans detail the integration of a powerful 220V 2.2kW water-cooled spindle, essential for efficient CNC machining operations. The spindle's uniform body is set into the Z-axis, bringing it close to the Y and Z-axis bearings for optimal rigidity and precision. Heavy-Duty Mechanical Movement Step-by-step guidance on setting up roller chain systems for the X and Y axes, driven by heavy-duty 651 oz-in stepper motors. The Z-axis utilizes a high-accuracy lead screw driven by a 425 oz-in stepper motor, crucial for precise CNC cutting. This robust setup ensures smooth and accurate movements across all axes. Counterbalanced Z-Axis Design The Z-axis assembly, weighing approximately 30 pounds, is counterbalanced using a constant force spring tucked into the gantry. This innovative design ensures smooth vertical movements and reduces strain on the motors, enhancing the machine's longevity and performance. Durable Materials & Construction Learn to build a CNC router using robust materials like Medium Density Overlay (MDO) for moisture resistance. The machine's structure is designed for optimal rigidity and durability, ensuring it stands up to rigorous use over time. Wall-Mounted Efficiency The machine's ribs are spaced 16 inches on center, allowing for easy fastening to wall studs using provided brackets. Adjustable rib feet accommodate floor irregularities, ensuring stability even on uneven surfaces. This smart design maximizes workspace efficiency without compromising on functionality. Optimized for Small Workspaces The vertical orientation and compact design mean you don't have to sacrifice valuable workspace. The greenLean v2 fits seamlessly into small workshops or multipurpose areas, making high-quality CNC machining accessible to those with limited space. Advanced CNC Electronics Setup Detailed wiring plans are included for incorporating either a Mach3 USB controller or a standalone CNC controller, complete with NEMA 34 and NEMA 23 stepper motors. This comprehensive guide is essential for anyone interested in CNC electronics and automation, simplifying the process of setting up your machine's brain. Important Notes Ceiling Height Requirements: The greenLean v2 CNC machine requires a minimum clear height of 80 inches, but more if you intend to access the top of the machine. Standard ceiling height is generally 96 inches (8 feet), which accommodates the machine comfortably. Machine Dimensions: The length of the machine is 116 inches (9 ft 8 in), so ensure you have adequate wall space for installation. Professional Installation Recommended for Spindle: The 2.2kW water-cooled spindle requires additional wiring and plumbing equipment. We recommend seeking a licensed electrician for installation to ensure safety and optimal performance. Digital Download Policy Due to the nature of digital content, our store policy does not offer refunds for digital plan purchases. Once a digital plan is bought and delivered, it's considered used and cannot be returned. This is because digital items are immediately accessible and cannot be physically returned or verified as unused. Additionally, once the digital plans are downloaded, we have no way of ensuring they are removed from your computer or devices, further complicating the possibility of returns. Please ensure the digital plan meets your requirements before making a purchase. Your understanding and acknowledgment of this policy are appreciated.

Share