NaN

/

of

-Infinity

BuildYourCNC

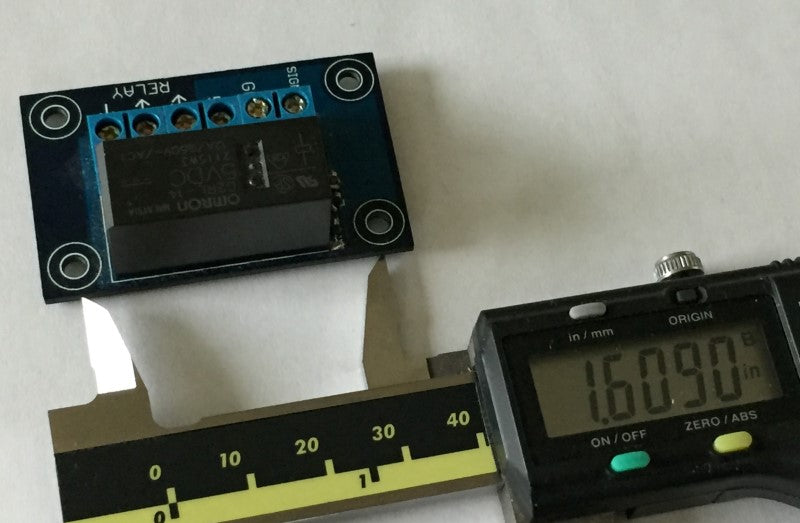

Relay Board to Switch on Electrical Devices

Relay Board to Switch on Electrical Devices

Regular price

$9.95 USD

Regular price

Sale price

$9.95 USD

Unit price

/

per

Couldn't load pickup availability

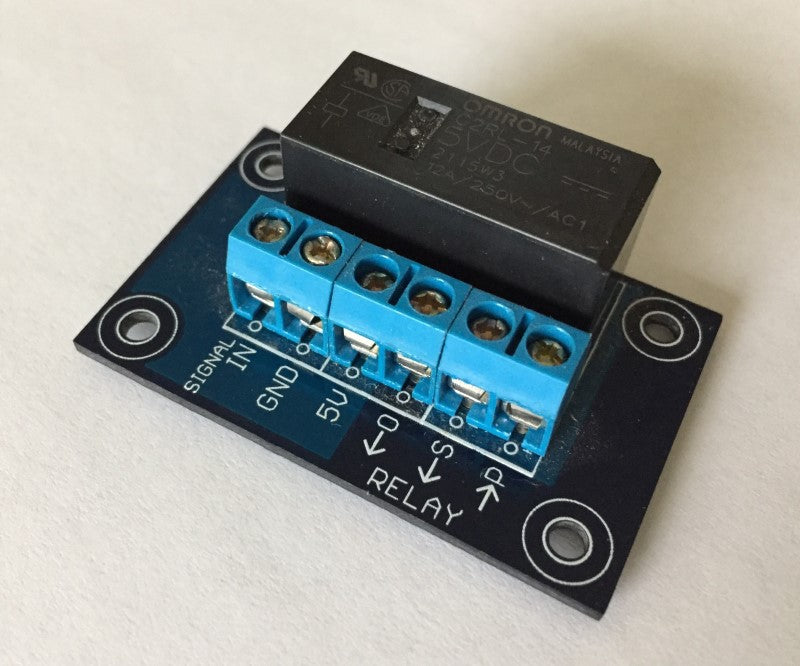

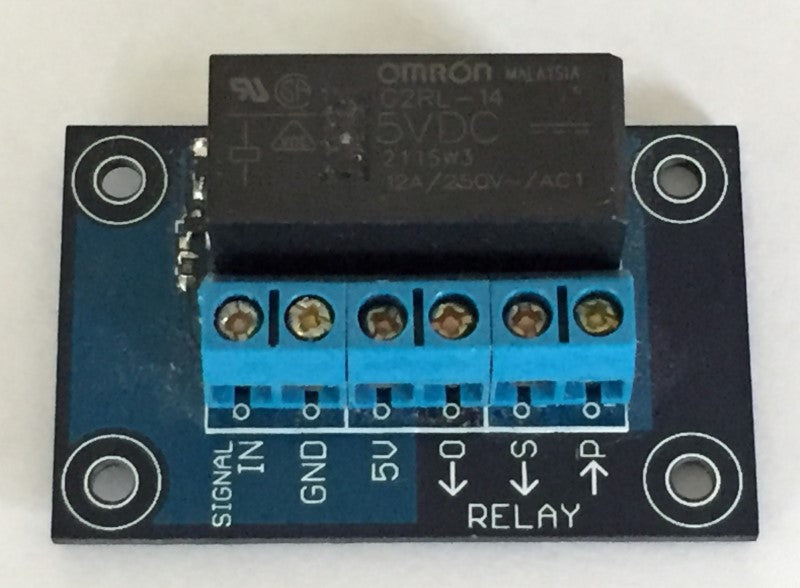

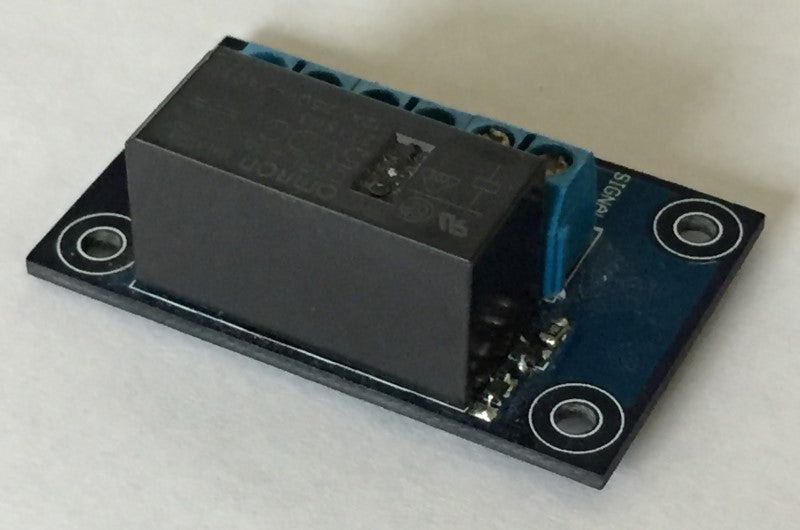

The relay board will turn on standard electrical devices up to 12 amps and 250 volts using a standard 5v signal. A relay board acts like an automatic switch to turn on and off electrical devices and appliances. The relay board has the capability of turning on and off devices that typically plug in to the wall outlet, but many more types devices can be operated from this relay switch. If a 5v signal is applied to the relay board, then the relay makes a connection between the P and O terminals and breaks the connection between the P and S terminals. Therefore, you can have things turned on in scenarios where the 5v is applied or if the 5v is not applied, depending on how it is wired.