1

/

of

2

BuildYourCNC

Motion 18 AWG Cable - Multiple Conductors

Motion 18 AWG Cable - Multiple Conductors

Regular price

$1.50 USD

Regular price

Sale price

$1.50 USD

Unit price

/

per

Couldn't load pickup availability

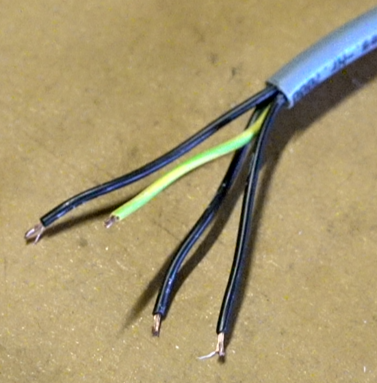

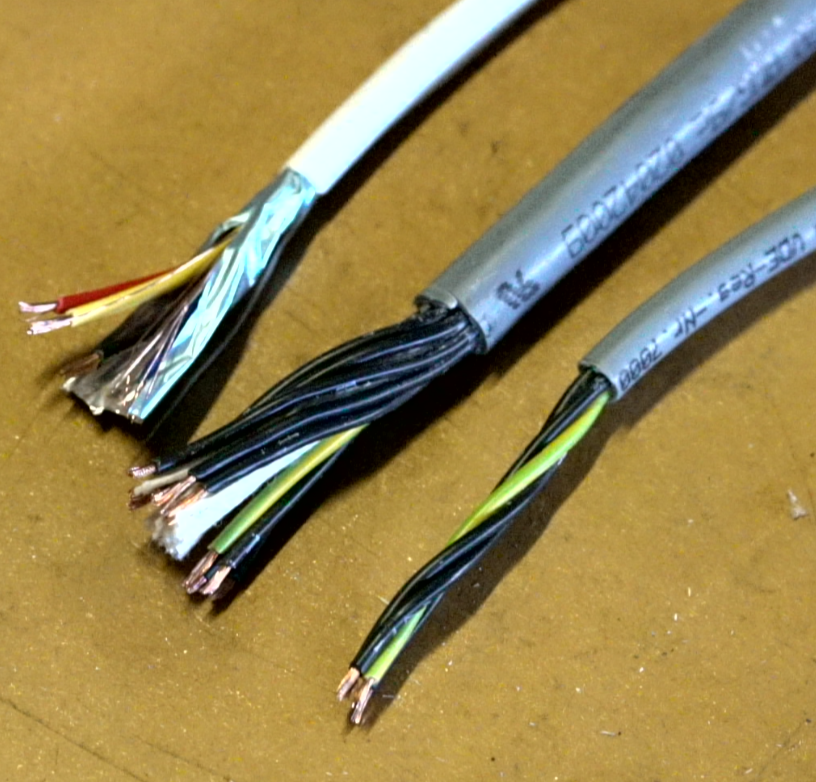

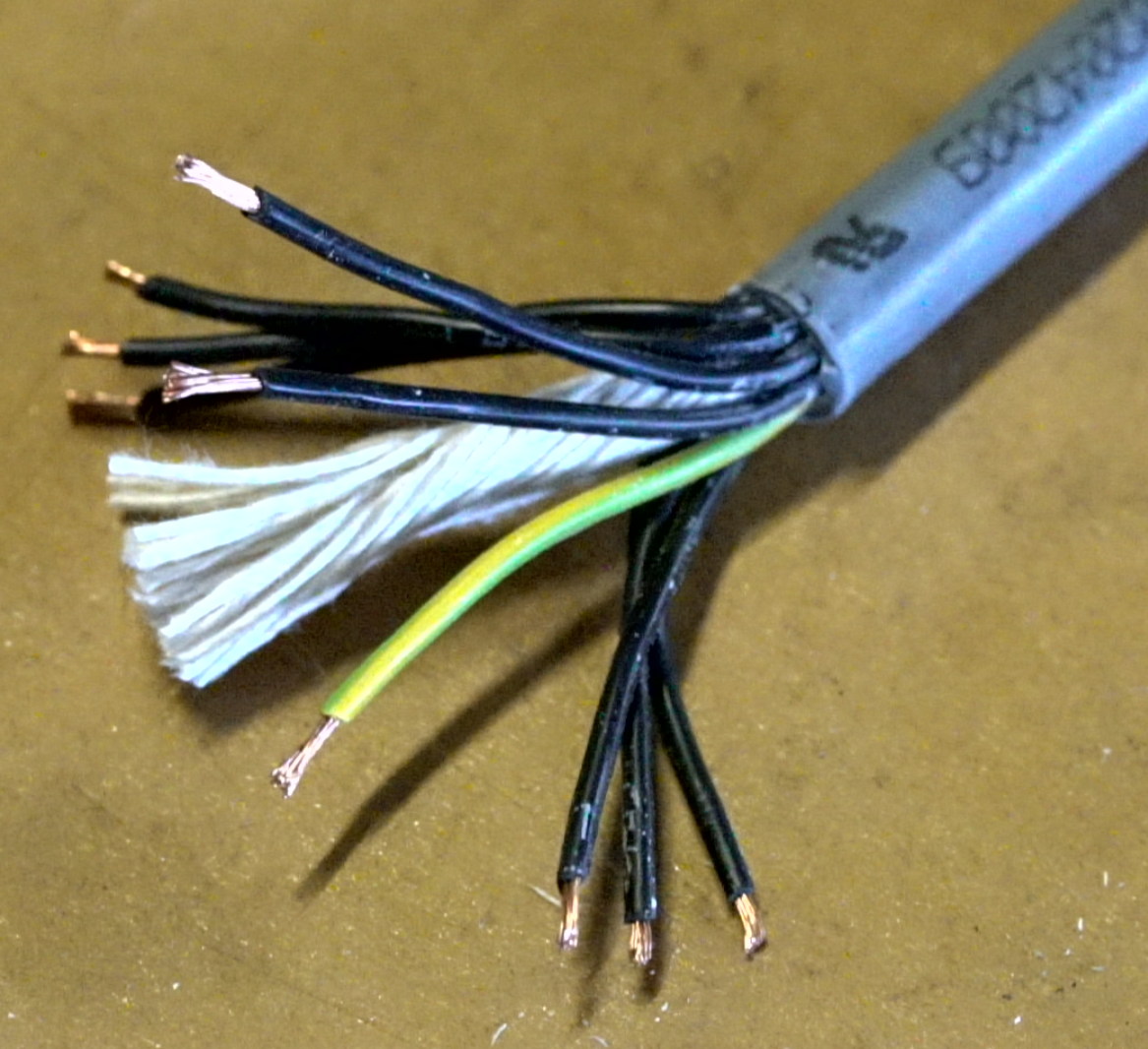

This cable is typically used for motor wiring from the drivers to the stepping motors. There are multiple wires within the gray jacket (called conductors). Specs: Unshielded, stranded copper, PVC jacket material, meets CSA/CE/UL specifications, The individual wire insulation has the conductor number labeled so color coding is not necessary. Here is a handy link to learn about wire gauges and current handling capacity 18 AWG

4 Conductors

Unshielded

Stranded copper

PVC jacket material meets CSA/CE/UL specifications

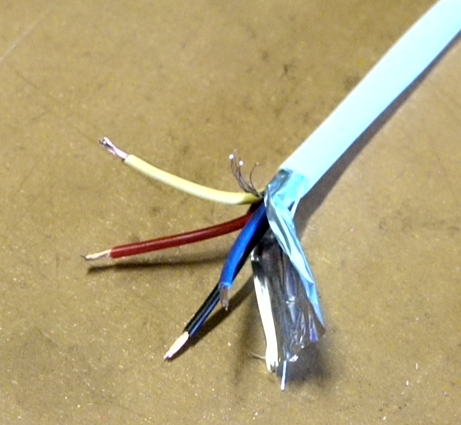

The shielded cable option has 4 conductors and is color coded rather than numbered.

4 Conductors

Unshielded

Stranded copper

PVC jacket material meets CSA/CE/UL specifications

The shielded cable option has 4 conductors and is color coded rather than numbered.

Share