1

/

of

10

BuildYourCNC

Small All Metal E-Stop (Emergency Stop) Button

Small All Metal E-Stop (Emergency Stop) Button

Regular price

$13.99 USD

Regular price

Sale price

$13.99 USD

Unit price

/

per

Couldn't load pickup availability

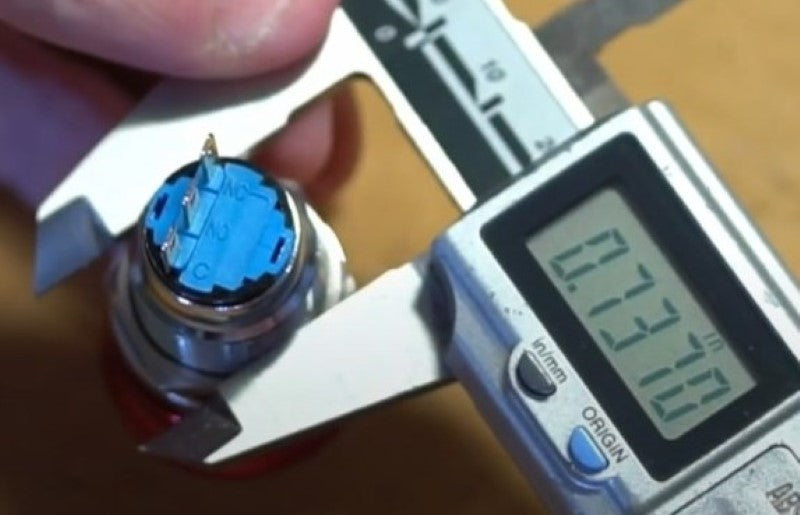

In the event that your CNC Machine goes rogue and seems hell-bent on self-destruction, consider this lifesaver: an all-metal emergency stop button. It's equipped with three leads, compatible with both NC (Normally Closed) and NO (Normally Open) configurations. To halt the chaos, just give it a push; a twist will set things back in motion. Enhance your CNC machine's safety with our robust Panel Mount Emergency Stop Switch, designed for easy integration and reliable performance. This switch features a distinctive mushroom cap button that activates with a firm press. To reset, simply twist the button in a clockwise direction, following the clearly marked arrows. This action triggers a mechanical release, allowing the button to snap back into its original position.

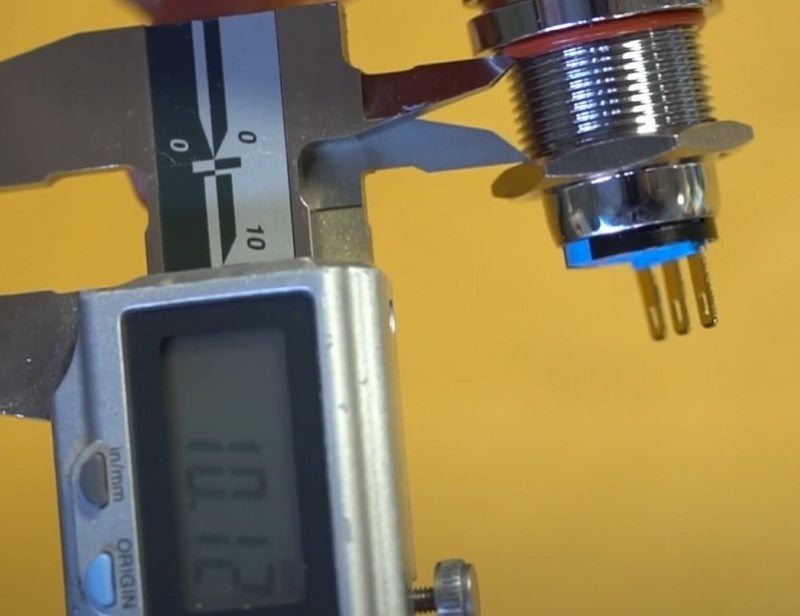

Installation is straightforward: prepare a panel hole measuring 3/4 inch or 19mm in diameter, ensuring it does not exceed 23mm or 0.9 inches. The switch securely attaches to the panel using the included nut. An o-ring accompanies the package, ensuring a tight seal against dust and moisture ingress, and also acts as a cushion to dampen the impact of a hard press, a common occurrence during emergency stop scenarios. This feature is essential for maintaining the integrity of your CNC machine's control panel. The threaded portion of the switch extends approximately 14mm, accommodating panel thicknesses up to 10mm or 0.39 inches, with the nut partially threaded.

Installation is straightforward: prepare a panel hole measuring 3/4 inch or 19mm in diameter, ensuring it does not exceed 23mm or 0.9 inches. The switch securely attaches to the panel using the included nut. An o-ring accompanies the package, ensuring a tight seal against dust and moisture ingress, and also acts as a cushion to dampen the impact of a hard press, a common occurrence during emergency stop scenarios. This feature is essential for maintaining the integrity of your CNC machine's control panel. The threaded portion of the switch extends approximately 14mm, accommodating panel thicknesses up to 10mm or 0.39 inches, with the nut partially threaded.

Constructed predominantly from durable metal, this ESTOP button guarantees longevity and resistance to wear. Only the lead connections and the o-ring feature high-quality plastic for optimal functionality. The switch offers versatile wiring options with three leads: NC (Normally Closed), NO (Normally Open), and C (Common). In the NC configuration, the NC and C leads remain connected until activation, at which point they disengage. Conversely, in the NO setup, the NO and C leads are initially separate, establishing a connection only upon the button's activation. This versatile, easy-to-install emergency stop switch is an essential addition for enhancing the safety and operational efficiency of your CNC machinery.

Constructed predominantly from durable metal, this ESTOP button guarantees longevity and resistance to wear. Only the lead connections and the o-ring feature high-quality plastic for optimal functionality. The switch offers versatile wiring options with three leads: NC (Normally Closed), NO (Normally Open), and C (Common). In the NC configuration, the NC and C leads remain connected until activation, at which point they disengage. Conversely, in the NO setup, the NO and C leads are initially separate, establishing a connection only upon the button's activation. This versatile, easy-to-install emergency stop switch is an essential addition for enhancing the safety and operational efficiency of your CNC machinery.  Ultimate Guide to Limit Switches, Proximity Sensors, and Emergency Stop Switches. Video to connect an E-Stop to the pokeys57CNC controller: For Mach4 For Mach3 Video to connect limit switches to the Mach3 USB controller (same wiring for e-stops):

Ultimate Guide to Limit Switches, Proximity Sensors, and Emergency Stop Switches. Video to connect an E-Stop to the pokeys57CNC controller: For Mach4 For Mach3 Video to connect limit switches to the Mach3 USB controller (same wiring for e-stops):

Installation is straightforward: prepare a panel hole measuring 3/4 inch or 19mm in diameter, ensuring it does not exceed 23mm or 0.9 inches. The switch securely attaches to the panel using the included nut. An o-ring accompanies the package, ensuring a tight seal against dust and moisture ingress, and also acts as a cushion to dampen the impact of a hard press, a common occurrence during emergency stop scenarios. This feature is essential for maintaining the integrity of your CNC machine's control panel. The threaded portion of the switch extends approximately 14mm, accommodating panel thicknesses up to 10mm or 0.39 inches, with the nut partially threaded.

Installation is straightforward: prepare a panel hole measuring 3/4 inch or 19mm in diameter, ensuring it does not exceed 23mm or 0.9 inches. The switch securely attaches to the panel using the included nut. An o-ring accompanies the package, ensuring a tight seal against dust and moisture ingress, and also acts as a cushion to dampen the impact of a hard press, a common occurrence during emergency stop scenarios. This feature is essential for maintaining the integrity of your CNC machine's control panel. The threaded portion of the switch extends approximately 14mm, accommodating panel thicknesses up to 10mm or 0.39 inches, with the nut partially threaded.

Constructed predominantly from durable metal, this ESTOP button guarantees longevity and resistance to wear. Only the lead connections and the o-ring feature high-quality plastic for optimal functionality. The switch offers versatile wiring options with three leads: NC (Normally Closed), NO (Normally Open), and C (Common). In the NC configuration, the NC and C leads remain connected until activation, at which point they disengage. Conversely, in the NO setup, the NO and C leads are initially separate, establishing a connection only upon the button's activation. This versatile, easy-to-install emergency stop switch is an essential addition for enhancing the safety and operational efficiency of your CNC machinery.

Constructed predominantly from durable metal, this ESTOP button guarantees longevity and resistance to wear. Only the lead connections and the o-ring feature high-quality plastic for optimal functionality. The switch offers versatile wiring options with three leads: NC (Normally Closed), NO (Normally Open), and C (Common). In the NC configuration, the NC and C leads remain connected until activation, at which point they disengage. Conversely, in the NO setup, the NO and C leads are initially separate, establishing a connection only upon the button's activation. This versatile, easy-to-install emergency stop switch is an essential addition for enhancing the safety and operational efficiency of your CNC machinery.  Ultimate Guide to Limit Switches, Proximity Sensors, and Emergency Stop Switches.

Ultimate Guide to Limit Switches, Proximity Sensors, and Emergency Stop Switches. Share