BuildYourCNC

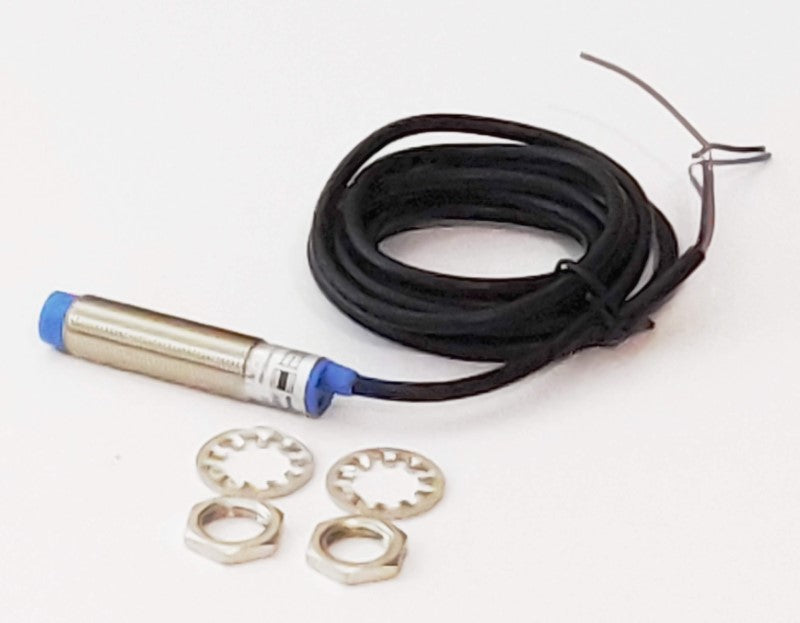

Inductive Proximity Sensor Switch

Inductive Proximity Sensor Switch

Couldn't load pickup availability

Use a proximity sensor switch to signal a machine (i.e. CNC router or laser machine) that it has reached an end or home position. This is an inductive proximity sensor detection switch. - Switch transistor type polarity: PNP, or NPN (depending on purchase option) - Voltage Range: 6VDC to 30VDC - Detection distance from a conductive material: 4mm - Normally Open type switch: Should be connected in Parallel or on a single input - 4mm distance activation

Inductive Proximity Sensor Technical Specification

Basic Operation

- Detects conductive metals (ferrous materials) without physical contact

- Activates when ferrous metal approaches within 4mm of the sensor tip

- Features an LED indicator that illuminates when activated

- Solid-state design eliminates mechanical bounce issues

Electrical Specifications

- Operating voltage: 6-36V DC (optimized for 24V DC industrial systems)

- Configuration: NPN, Normally Open (NO)

- Three-wire connection:

- Brown wire: Positive (V+)

- Blue wire: Negative (V-)

- Black wire: Signal output

Signal Behavior

- Normal state (no metal detected): Black wire outputs ~24V

- Activated state (metal detected): Black wire outputs ~0V

- Detection occurs only at sensor tip, not along sides

- Signal is clean and bounce-free due to solid-state design

Mounting Features

- Threaded cylindrical body for secure mounting

- Includes mounting nuts for position adjustment

- Can be mounted in two configurations:

- Static sensor with moving metal target

- Moving sensor with static metal target

- Requires appropriate mounting hole in machinery

Installation Considerations

- Should be protected from metal chips in machining environments

- Compatible with common CNC controllers (e.g., Mach3 USB, Pokeys57CNC)

- Can be used as limit switches in industrial machinery

- Requires proper grounding and common V- connection for multiple sensors

Integration with Mach3 CNC Software

- Connects to controller input terminals (IN1-IN4)

- Requires specific configuration in Mach3 software:

- Port and pin assignment in "Ports & Pins" settings

- Axis designation (X++, etc.) based on installation position

- Can be verified through diagnostics tab

Share

Questions & Answers

Have a Question?

-

Thanks for the oportunity to ask, I am building a cnc and using npn closed sensors could you help me with the conection of these, do i still connect them in series if i use more than two in each axis. Also you mention that a stop switch should be connected grd and input to the controller would that be done after the 24v power supply. Thanks r

If the sensors are NC (normally closed) you can wire them in series. If the sensors are NO (Normally Open) you can still wire them to the same input, but the wiring needs to be in parallel (like a ladder). I have more information on the following video: https://www.youtube.com/watch?v=d7zdo86oGig

-

Does it make a difference if I use a PNP instead of an NPN?

It changes the polarity of the switch, therefore you will need to connect it accordingly, and also set your pins properly. Check out this video - https://www.youtube.com/watch?v=noq5I5b8yTQ