BuildYourCNC

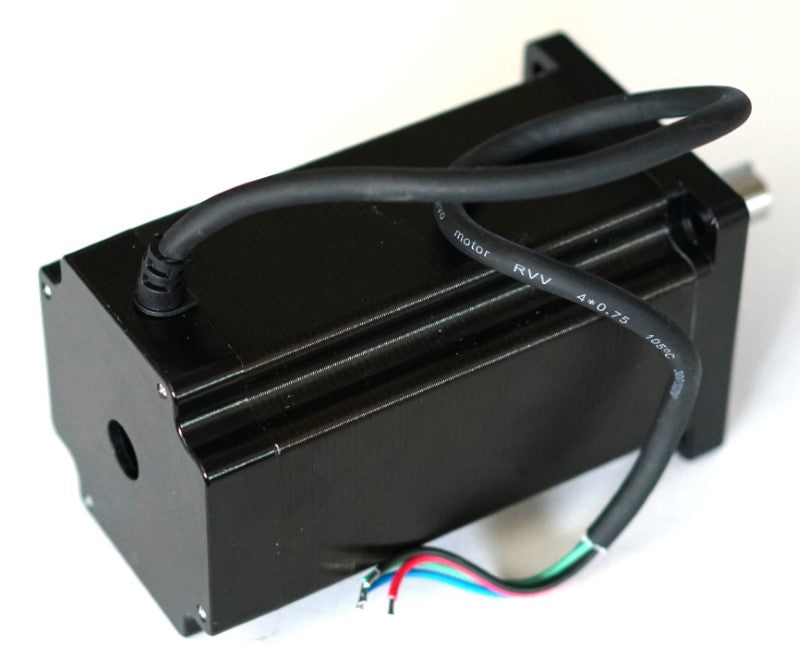

NEMA 34 Stepper Motor (1699 oz-in 14mm single shaft) 6 Amps

NEMA 34 Stepper Motor (1699 oz-in 14mm single shaft) 6 Amps

Couldn't load pickup availability

Affiliate Links

Description: NEMA 34 Stepper Motor 6A 12Nm (1700 oz-in)

Price: $70.00 USD

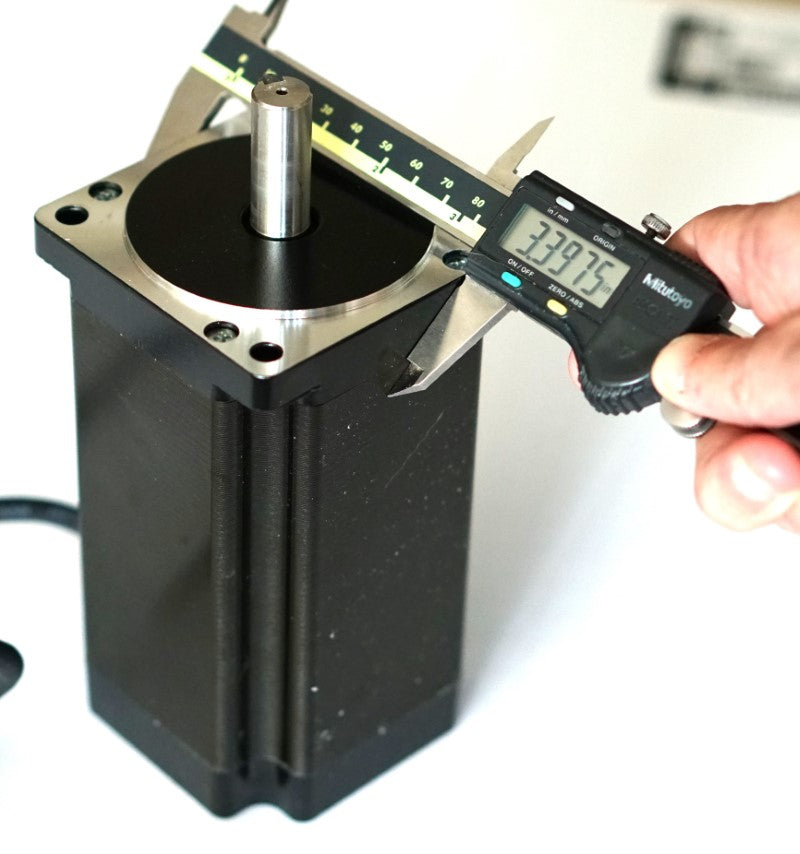

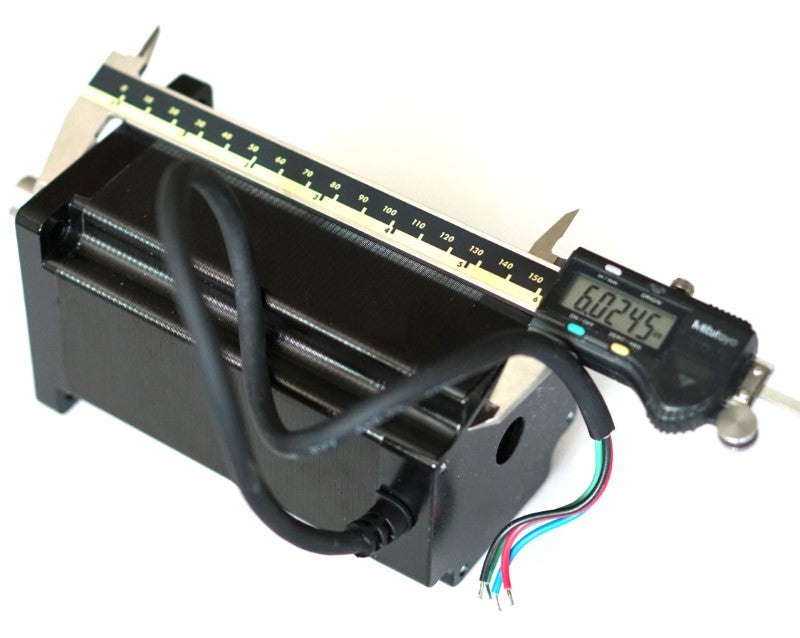

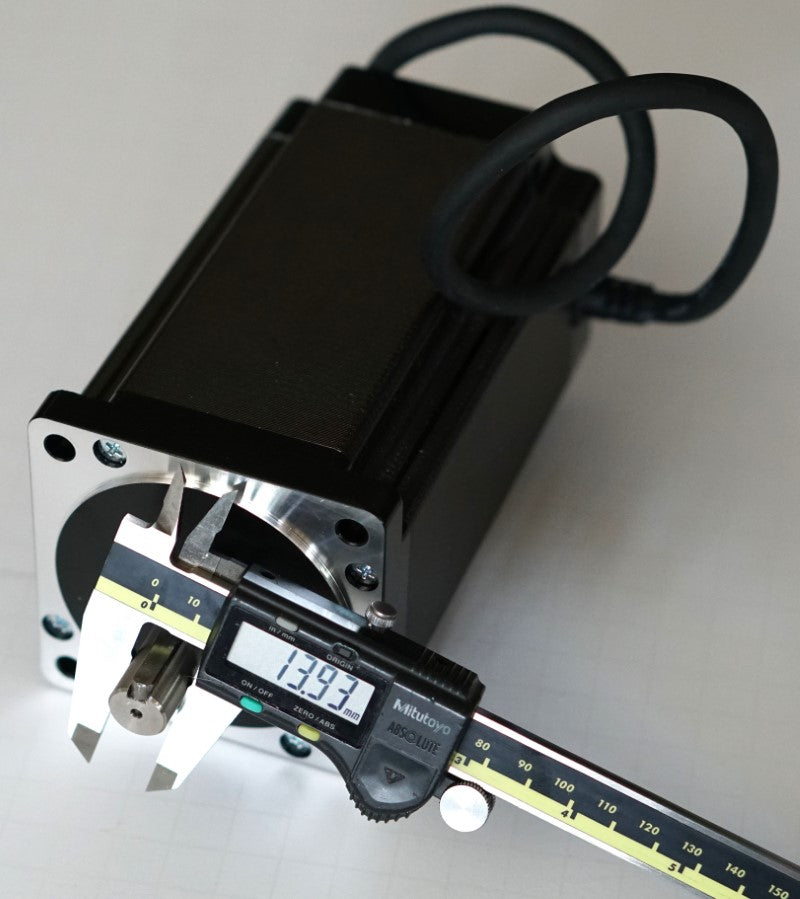

See ProductThis stepping motor has a large frame size and torque and can be used where a great amount of weight is carried and where high load against the motor turning direction is present. A single shaft motor with a diameter of 14mm or .55 inches. There is a keyway on the shaft. The motor rated torque is 1699 oz-in or 12 Nm (Newton Meters). This is a very strong motor which will provide enough torque for heavy gantries and high acceleration. Wiring: Black to A+, Green to A-, Red to B+ and Blue to B- Steps: Standard 200 steps per rotation and can be microsteped using drivers that feature microstepping. The degree per step is 1.8. Size: NEMA 34, or 3.4 x 3.4 inches outer frame (face) dimension or 86mm x 86mm. The length of the motor not including the shaft is 151mm. The length of the shaft is 37mm. The mounting dimension is 70mm. Electrical: Amps per phase is 6.0 amps

Share