BuildYourCNC

HIWIN Spec Linear Guide Rail

HIWIN Spec Linear Guide Rail

Couldn't load pickup availability

- Rail: 1400mm guide length

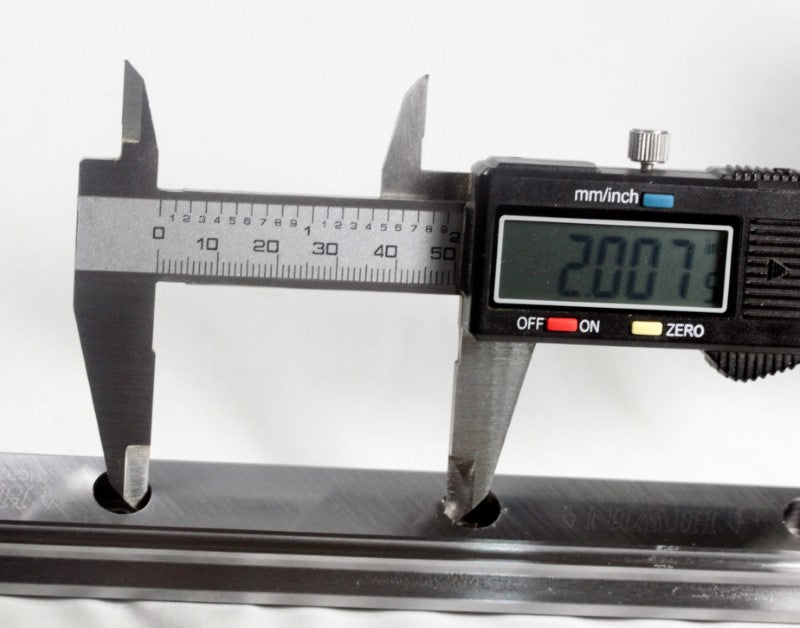

- Rail width: 20mm

- Mounting bolt: M5x16

- Mounting hole center to hole center: 60mm

- Guide Block: Width of block: 63mm

- Length of block: 77.5mm

- Mounting holes distance in the width direction: 53mm

- Mounting holes distance in the length direction: 40mm

- Both: From bottom of rail to top of block: 30mm

- From block bottom to bottom of rail (clearance): 4.6mm

Share

Questions & Answers

Have a Question?

-

if I order the aluminum rail seperately does it come pre-drilled with the the mounting holes?

We can drill the holes for you. Just give us the desired measurement from hole to hole (on center). The drill size is 5/16" and the hole will be centered between the inside curve of the aluminum and the start of the curve at the edge.

-

I am trying to build a cutoff saw adjustable fence belt driven i need a linear rail 8 feet long it has a min. working load suggestions?

Are you specifically asking for the axial load, or load on the mechanics which will drive the fence by the stepper/servo motor?

-

How do I specify multiple quantities of custom cut lengths of the linear bearing guide?

Purchase the total length of the product that interests you (i.e. the linear bearing guide) and call us to inform us how you would like it cut. The phone number is located at the top right of each web page by hovering over the "Need Help?" message.

-

Do you sell the HIWIN rail sections without guide blocks?

Yes, we sell rails with HIWIN specification. Our HIWIn spec rails are interchangeable with HIWIN brand rails. Here is the link for our per inch product page. https://www.buildyourcnc.com/item/mechanical-rails-HIWIN-Linear-20mm-Guide-Rail

-

Are the Hiwin rails in stock yet?

For more information regarding this item please contact bycncmanufacturing@gmail.com. This answer will be erased when this item is in stock.

-

About your HIWIN rails. What Carriage block does the 78" rails come with, 2 flange or 2 with no flange?

The HIWIN rails come with the same flange blocks that are sold individually.

-

Can I butt multiple rails end to end for a longer distance?

Yes, you can abutt sections of this rail. You may need to grind the ends of each to make the motion from one rail to the other smooth. Make sure that the rail is aligned as straight and as close as possible as the bearing block is very tight and will bind if this is not aligned perfectly. Make sure there is no gap between the sections where ball bearing can escape.