1

/

of

7

BuildYourCNC

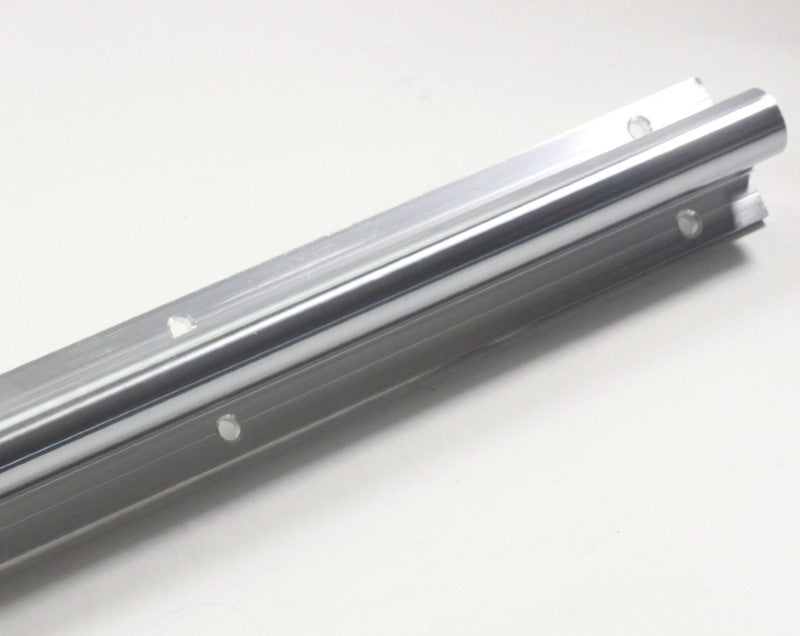

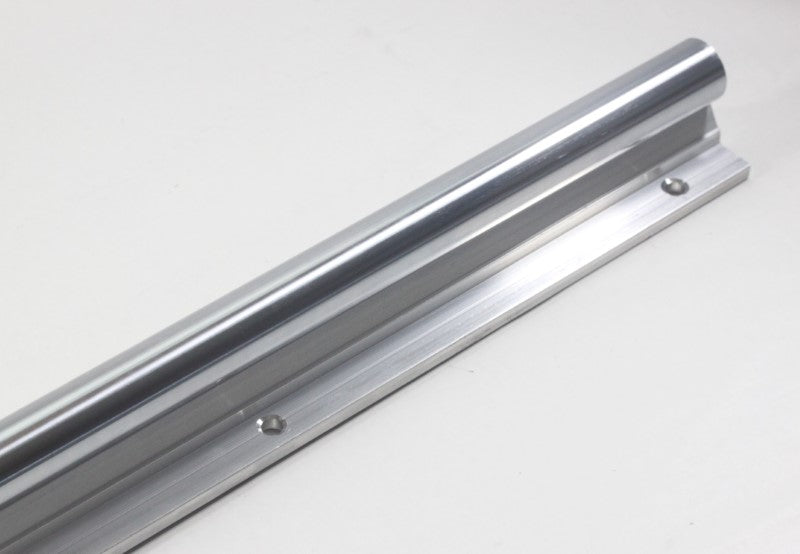

Linear Guide Rail 20mm (0.78")OUT OF STOCK

Linear Guide Rail 20mm (0.78")OUT OF STOCK

Regular price

$2.50 USD

Regular price

Sale price

$2.50 USD

Unit price

/

per

Couldn't load pickup availability

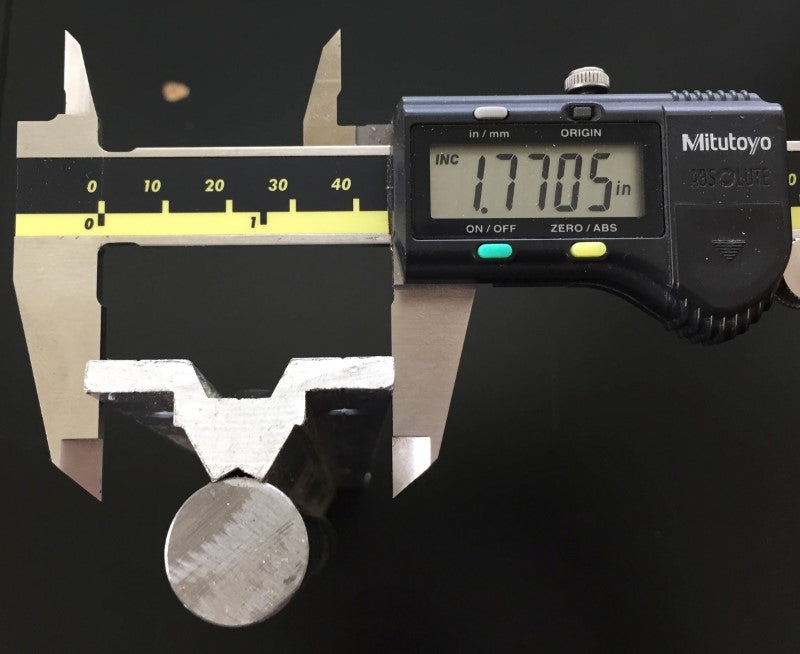

We now offer Linear Guide rails made of high-quality hardened steel to add a new dimension of reinforcement to your machine. These rails pair with our 20mm Linear Ball Bearing Blocks. Order Info: add desired length in inches to cart (QTY 1 = 1") , if multiple lengths are needed, please contact us to let us know. These SBR20 round linear guide rail should be ordered in increments of 11 inches in order to provide you with 2 sets of mounting holes on both sides. These will pair with our 20mm Linear Ball Bearing Blocks Material: Grc15 steel Hardness: HRC60-HRC62 Guide Width: 20 mm (0.78 in) Overall Height of Rail and Base: 37 mm (1.46 in) Width of Base: 45 mm (1.77 in) Mounting Holes on Center Widthwise: 30.226 mm (1.19 in) Mounting Holes on Center Lengthwise: 150 mm (5.9 in) Note: Maximum single length for 1 piece of Linear Guide rail is 1400mm or 55.11 inches

Share