BuildYourCNC

Mach4 CNC Control Software

Mach4 CNC Control Software

Couldn't load pickup availability

- Type C (Fanuc) cutter compensation standard in Mach4.

- More accurate tool path compensation for different size tools

- Improved Anti-gouging

- Synchronous Motion of up to 6 completely separate coordinate systems (instances) at the same time.

- Multiple heads, machines and processes to produce complex parts.

- Asynchronous Motion (out of band axis) to control uncoordinated motion.

- Pre-change tool changers

- Robotic Loaders

- Torch height manual compensation control

- Multi-Axis Work Shifts and Head shifts to offset cutting tool path for multiple work piece holders and fixtures.

- Remote Control of machinery (IPC)

- Control or track CNC equipment from a remote location

- Greatly expanded troubleshooting

- Track the operation of equipment

- Link information between other computer applications Excel, etc

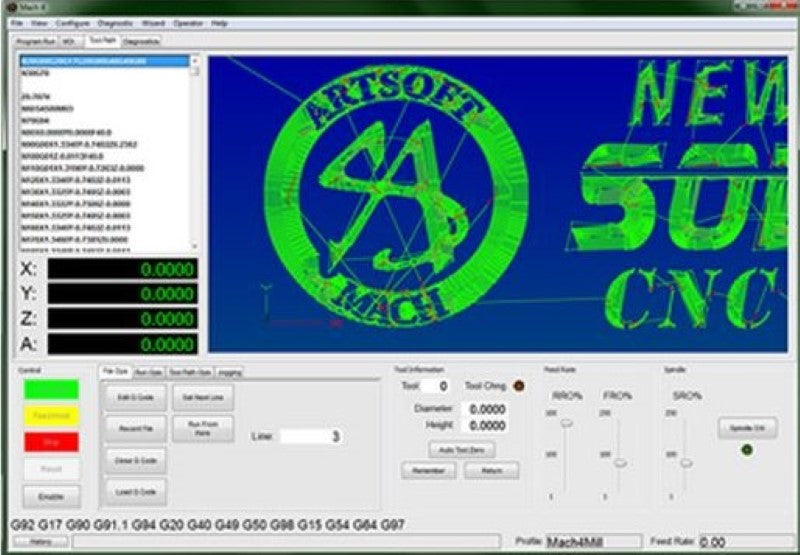

- New Dynamic tool path display

- View, rotate, pan, and scale the tool path quickly and easily to ensure G-code is creating the path you expect.

- Improved screen layout and easily customizable screen modification tool.

- Change buttons, displays, and indicators easily, quickly, and on the fly! Parallel Port Legacy Plug-in: For compatibility with Parallel Breakout Boards, Mach4 requires an additional $25 purchase for the legacy driver to run off the parallel breakout system. Mach4 Industrial Additional Features Tool Life Management (G10 L3 command), Screw Mapping Professional Screen Designer (advanced G.U.I.) - Screen Animation Control - Screen Integrated Tool Table Control - Screen Integrated Work Offset Control - Screen Integrated gcode editor - Screen Artsoft Wizard Package Integration Macro B gcode Programming (#variables) - User definable gcodes via marco calls - Macro Calls: G65, G66, G66.1 - gcode via marco call (custom G codes via macro B) - mcode via macro call (custom M codes via macro B) - mcode via sub code (custom M code via sup program) - Conditional gcodes - set VN call - define variable names gcode Editor Included Phone support with the developer with priority support. Mach4 Registration Instructions:

- Download the demo version of Mach4 Hobby here

- After installation, run Mach4 Mill

- Navigate to "Help" tab on the top menu and select "About"

- Copy Your PC-ID number and include it in the notes when purchasing or email it to customerservice@buildyourcnc.com with subject line "Mach4 PC-ID for -your name-"

- Once we have your PC-ID we will send you the license file that will register your copy of Mach4 and email you the license zip file

- After receiving the file containing your license, save the file into a folder on the same computer you have installed Mach4 on.

- Open Mach4 Mill and navigate to Help and About again.

- Click on "Load License File" and select the license file you have just saved. You will receive a confirmation message that Mach4 is registered and you will be asked to restart your computer.

Share

Questions & Answers

Have a Question?

-

Is there an interface board that now works with Windows 11?

Both Mach3 USB controller and the Pokeys57CNC controller work with windows 11. However, I would recommend the Pokeys57CNC since you are able to use either Mach3 or Mach4.

-

Do I use the blue brew BOB that I purchased in conjunction with the Mach 4 PPL Plug-in provided with Mach 4 software when I purchase It?

Yes, you will need the Mach4 legacy plugin to make the parallel port and Breakout board work.

-

I reciently purchased Mach 4 and sowenloaded the license. After creating the profile and working with the program it is still in the demo mode. The drop down tells me that it is sucessfully installed. Please help.Thanks

After you purchase the license, we provide you with the license file. That file needs to be manually copies to your mach3 folder. The mach3 folder is usually on the C: drive (C:Mach). Copy the file that was emailed and copy it to the c:Mach3 folder. Go to the about menu option in Mach3 and confirm that your name is on that dialog box. Additional Information: My name is not on the dialog box Additional Information: Its mach 4 dumass

-

I purchased Mach 4 control software and am in need of a very elementary tutorial on set up. I am extremely new to this and need step by step help. Thanks

The best place to find information and step by step instructions for Mach4 is to use the manuals provided by MachSupport.com. Here is a link to the PDF manuals for Mach4: http://www.machsupport.com/help-learning/product-manuals/

-

I just bought the 3 axis w/heavy gantry, will Mach 4 run well with this, and how large can I go with the cut area

Yes Mach3 is a great program. Our 3 axis is 6'X12'X3'using all BYCNC components (incl. redsprout)

-

I have a 3 axis combo w/ parallel breakout board. Will this work with Mach 4?

Our electronics kits with the parallel breakout board will work with Mach 4, however you will need to purchase the Legacy Driver for Mach 4 to work with our breakout board.

-

How do I recover my MACH4 hobby license?

To recover your Mach4 hobby license, email us the PC-ID (in the help-about section of Mach4). If this is a new computer you are trying use for Mach4, email us the old PC-ID, or your name if you don't have that PC-ID anymore, and the new PC-ID so we can re-issue a license for the new computer. Additional Information:

-

Hello to all the team. I wonder if the MACH 4 software is multiling or not ... Thank you for your reply, best regards. Andr�.

Currently on our first version of MACH 4 that we have received, it was only included with English and German. We believe in the future updated versions of MACH 4 will have plugins, add-ons, or additional files to add additional languages. But at its current state it only is included with English and German.

-

I have a Shark HD520 and will I have to change all of my controller cards?

If the Shark HD520 has separate drivers for each stepper motor, you will only need to change the controller that connects the computer to the drivers. If the Shark HD520 has the controller and driver all on one board, then you will need to get a controller and one driver for each stepper motor. You can determine if your electronics have independent drivers by opening the electronics enclosure and checking for three boxes each having wires that connect to a stepper motor (or stepper motor connector.

-

I would like to build my cnc that is controlling by camera. There are 4 crosses on the sheet that is marked on laser. I need to make part zeroing according to 3 points on the part. I would like to ask, Does mach4 support camera that is make zeroing automatically?

Yes, you can use OpenCV to grab the video/image data and use the crosses as a detection object in OpenCV. Mach4 has Lua scripting capabilities, so you can create a script that takes the coordinates from the OpenCV image and set the machine's zero point accordingly.

-

The CNC is routing my letters half the size

In Mach4, you need to calibrate your axes so that real-world measurements are the same as the measurements for your axes' position. Mach4 has a wizard that allows you to calculate the steps per unit for an axis. This is a manual operation, so you will need to use the existing steps per unit in the axis you wish to change. Go to motor tuning to grab this number and copy it to the clipboard. Now go to the wizards menu and "select wizard". Scroll through the wizards until you see "StepsPerUnitCalculator" wizard and accept that wizard. A new dialog box will appear with fields that you can use to determine the new steps per unit for the desired axis. The incremental move button is available so you can test new values calculated for the steps per unit for the axis. Use the "move distance" along with the "move velocity" to incrementally move to determine move distances.

-

I wanted to know if I could use a computer with 64 bits windows installed (with Parallel port in the mainboard) or not. Thanks

Mach4 is designed to run in both 64 and 32-bit computers and operating systems, however, the parallel port interface will not work with 64-bit windows. The easiest solution would be to use a more modern CNC controller, like the: pokeys57cnc that I sell https://buildyourcnc.com/item/electronicsAndMotors-electronic-component-breakout-Mach4-mach3-USB-ethernet-Board Or other options like the Smoothstepper board that I do not sell. Both are great options.