BuildYourCNC

1/4" to 1/4" - Rigid Coupling (Steel) - (1/4" bores at each end)

1/4" to 1/4" - Rigid Coupling (Steel) - (1/4" bores at each end)

Couldn't load pickup availability

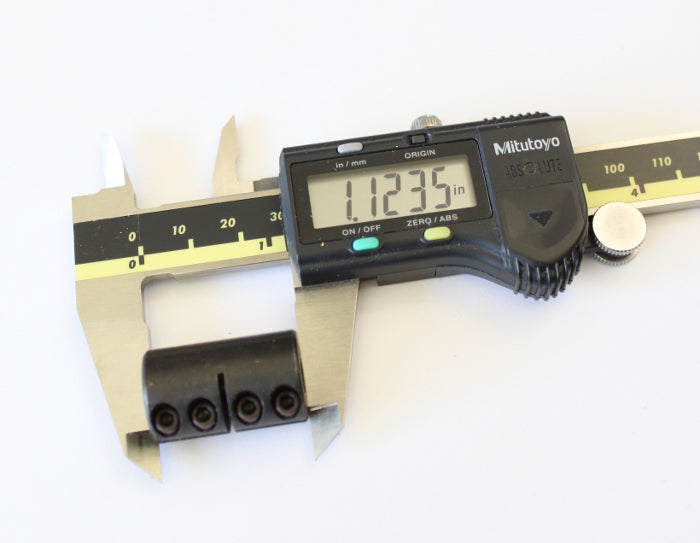

Rigid couplings will keep backlash to a minimum, since the coupling is one single piece. Generally, the motor shaft with a 1/4" diameter will be inserted in one end, and a shaft, or lead screw also measuring 1/4" in diameter will be inserted into the other end. The screws that clamp the shafts will be tightened. These steel clamping coupling are for use with high torque motors and high inertia when the motor is changing directions. This coupling is called a clamping coupling or clamp coupling. The length of this rigid coupling is 1.124 inches (28.55 mm). The diameter is 0.687 inches (17.45 mm). The tool needed to tighten the coupling is a hex key or allen wrench (not included) with a size of 3/32 inches. There are four screws in total, two for each shaft that is inserted into this coupling.

Share

Questions & Answers

Have a Question?

-

do you have the lovejove 1/4 x 1/2 couplings in stock and can they be picked up locally in the Houston Texas area?

We have a generic version of those couplings which are made of the same material and function exactly the same, but with two set screws for each hub rather than one. The coupling will be in stock unless otherwise noted on the product page for that particular coupling. Additional Information: Can the parts be picked up locally in the Houston Texas area?

-

The Data Sheet for 3/8 anti-backlash nut isn't showing up on website. Can you e-mail me or repost on website?

The 3/8" anti-backlash nut mates with our leadscrew (https://buildyourcnc.com/item/mechanical-leadscrews-lead-screw-!375-2-starts-10-tpi) where you will find the datasheet (mounting dimensions) for the antibacklash nut.

-

motors not working

Confirm that the port #1 address is correct (Mach3). - In Mach3, click on Config-> Ports and Pins. - If the parallel port is integrated on the mother board, then the address is probably 0x378 - If the parallel port is an adapter card: - click on start - right click on computer - click on manage - click on device manager (on the left) - Expand "Ports (COM & LPT)" - Right click on the LPT port to be used, click on properties - Click on the resources tab - Note the IO ranges that is presented to you - In Mach3 ports and pins screen, change the port #1 address to 0x followed by the first IO range number.

-

is there a pci express parallel card that supports mach 3 with windows 7

Any parallel PCI-E card should work with mach 3 and windows 7, but you will need to know the port that the card will be using (example: 0x378). In mach 3 go to Config/Ports&Pins/PortsSetup&AxisSelection Additional Information: Once the PCI adapter is installed. Check the device manager on that lpt port and look at the I/O range. You will need to use the first I/O address in the range for the port address entry in Mach3. Additional Information: Additional Information:

-

I have the heavy duty red leaf system. I am having an issue tuning the motors. It movesto the exact location in the negative direction, but i am gaining .375 inch on the possitive direction. I have 2 motors running the x axis.

What machine do you have the redLeaf system connected to? what mechanical system is used on the machine? It sounds like there may be some slippage in the mechanical system of the machine.

-

For the thread rod on the x asis, You have a device for the thread rod to ride through ?

For our machines the threaded rod will be included with only our whiteAnt, an it is only sustained with to nuts on each side where it goes through the structure. Nothing besides the structure is it riding through. For the scratch build kit, if a threaded rod is being used please refer to using a anti-backlash nut similar what we carry (https://www.buildyourcnc.com/item/mechanical-leadscrews-antibacklash-nut-!375-2-starts-10-tpi).

-

I need a Rigit Coupling that is 1/2" on one side and 5/16 on the other side.Can you get that for me?

We sell both coupling hubs that can be created to your specific needs. Which will be here https://www.buildyourcnc.com/couplings.aspx and would be the bottom coupling hub's, not the rigid couplings. So essentially you would get the Single 1/2" Coupling Hub and the Single 1/4" Coupling Hub, and etc. for different combinations.