BuildYourCNC

NEMA 17 CNC Motor (84 oz-in 5mm shaft) 1.68 Amps

NEMA 17 CNC Motor (84 oz-in 5mm shaft) 1.68 Amps

Couldn't load pickup availability

Affiliate Links

Description: Nema 17 Stepper Motor Bipolar 2A 59Ncm(84oz.in)

Price: $13.95 USD

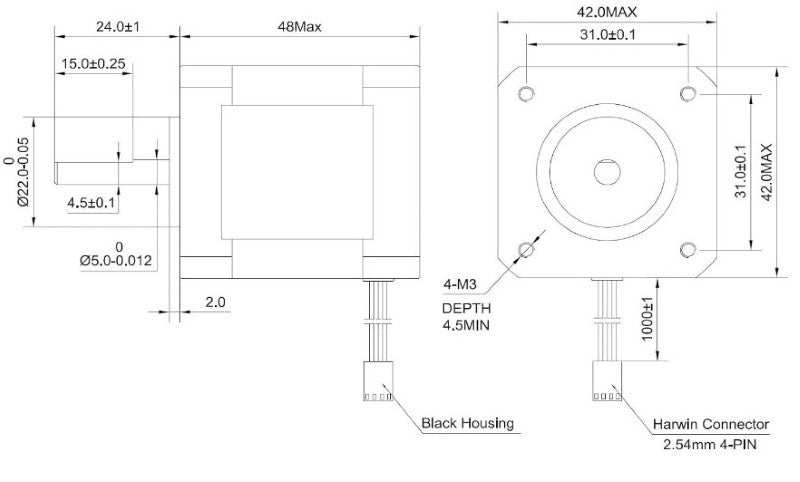

See ProductElevate your CNC, laser, or 3D printing projects with this Nema 17 Stepper Motor. This high-performance bipolar motor delivers precision and power in a compact package, making it an essential component for makers, hobbyists, and professionals alike. This NEMA 17 Stepper Motor (Model 17HS19-2004S1) is a versatile and reliable choice for various applications in CNC machines, 3D printers, and laser engravers. With its impressive 59Ncm (84oz.in) holding torque, this motor provides the strength and accuracy needed for demanding projects. Designed for optimal performance, this bipolar stepper motor features a 1.8-degree step angle, allowing for precise control and smooth operation. The motor's rated current of 2.0A per phase, combined with a phase resistance of 1.4 ohms, ensures efficient power usage and consistent output. Its low inductance of 3.0mH ±20% (at 1KHz) contributes to improved high-speed performance. Measuring 1.65" x 1.65" x 1.89" (42mm x 42mm x 48mm), this NEMA 17 motor fits perfectly into standard mounting systems. The motor comes equipped with a 1-meter (39.37") cable and a 0.1" pitch connector, making installation and integration into your setup quick and hassle-free. Constructed with high-quality materials, including stainless steel (40%), copper wire (30%), plastics (20%), and aluminum alloy (10%), this motor is built to last. Its durable construction ensures reliable operation even in demanding environments. Compatible with a wide range of drivers and controllers, this stepper motor operates optimally with a driving voltage between 12-24V, with 24V being the recommended voltage for best performance. For safety and longevity, always ensure that the motor is connected to a constant current or chopper drive controller before testing or operation. Whether you're upgrading your existing machine or building a new project from scratch, the NEMA 17 Stepper Motor offers the perfect balance of power, precision, and reliability. Its versatility makes it an excellent choice for various applications, including 3D printers, CNC routers, laser engravers, and other motion control systems. Upgrade your machine's capabilities and take your projects to the next level with the NEMA 17 Stepper Motor – the driving force behind precision and innovation in CNC, laser, and 3D printing applications.

Share

Instructions

Questions & Answers

Have a Question?

-

I ordered 96 inches of the 1/2 inch 10 tpi drive screw. I need it in 3 pieces. 53 inches, 30 inches, and 13 inches. Please let me know if that can happen. Thankyou

Yes. We will make sure the lead screw is cut to those dimensions. 53/30/13

-

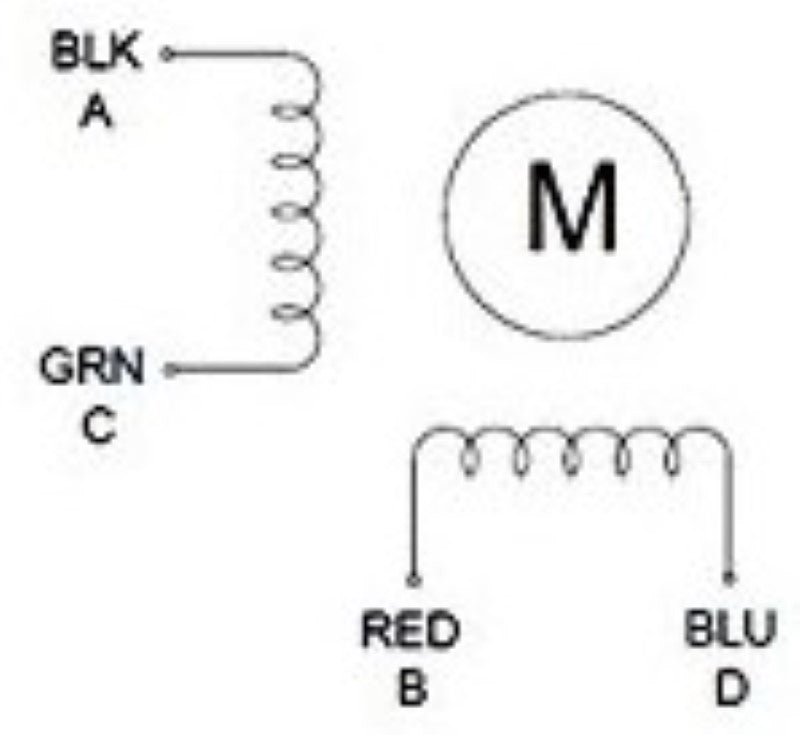

If motors are wired for Bipolar series which leads do you swap for rotation?

For our motors, drivers and power supplies, we recommend bipolar parallel (relating to motors with more than 4 wires). The current draw and voltage combination under bipolar parallel results in better performance. To reverse the motor spin direction for both bipolar series or bipolar parallel, switching the "A" wires with the "B" wires will do the trick.

-

I would like to design my own CNC router around one of your electronics bundles, either the 3 Axis - Heavy Gantry or 3 Axis - All Large Motors. Do you have the data sheets for the motors so that I can use the dimensions in my model?

You can find the datasheets to our motors be going to the the stepping motor category page https://www.buildyourcnc.com/category/nema and selecting the motor. This will bring you to the product page for the motor and all of the motor information will be found there.

-

I HAVE NOT SEEN ANY REFERENCES TO ENCODER FEED-BACK CAPABILITY IN OF THE HARDWARE YOU SELL. THIS A SUPPORTED FEATURE WITH HARDWARE/SOFTWARE SELL?

I haven't delved into using encoders with stepping motors too much. From my research, you need to have a controller that can provide the closed loop control, rather than software handling that process. I have also found from my research that using encoders on stepping motors is generally used to stop the machine in the case that the motor failed to achieve the commanded position for some reason and gives the user the chance to correct and continue with the job. If you want proper closed loop control, it may be best to go with servos and servo controller that provide the closed loop control within the real of those two components.

-

I have my motors wired like the wiring diagram I have two motors on Y axis how do I wire the second motor

To move two stepper motors simultaneously with the same signal, simply wire the two stepper motor drivers to the same interface board signal terminals (CP and CW). Additional Information: using a ardino uno controller and a cnc sheild on top of that how to wirer 2 motors to 1 axis its the x axis ?

-

I have followed all the "CNC Electronics 1 - 9" videos and I'm using almost the exact same components (motors run and sound good) but the motors are runing very hot in just 15min with no load - have I done something wrong or do steppers run very hot?

If your motors are hot to the touch, this is normal. Current is being drawn by the motor coils as the motor moves and as the motor stays at a position. If the motor is not using the current in the coils to move (holding it's position), the energy will be translated as heat (rather than motion, sound or light). Even while moving, some of the energy will be lost as heat. Remember that energy cannot be created nor destroyed. Additional Information: Additional Information: Additional Information:

-

I have constructed the cnc router machine as shown in woodsmith magazine. I have purchased the 3 Nema stepper motors. The one larger motor has 4 wires, as do the other two. However, on the schematic, the Z, and Y axis motors indicate 8 wires each. Did I go wrong, or are there different Nema 23 motors?

The 8 wire motors need to be wired in bipolar parallel configuration. The wiring is as follows: Red and Blue to A+, Yellow and Black to A-, White and Brown to B+ and Orange and Green to B-. To find the wiring for the 4 wire motors, the wiring is Red to A+, Orange to A-, Blue to B+ and Green to B-.

-

I have 8 wires wired to my driver in the right places. I need to know how to wire the relay Ken

There is no need to connect a stepper motor to a relay. The stepper motor driver controls the stepper motor completely.

-

I have 8 wires the red andblue are to A+ yellow and black are A- white and brown to B+ and green and orange to B- I don't have any more wires to wire to the relay

The stepper motor does not connect to a relay. The driver controls the stepper motor movement and direction.

-

I cannot turn the shaft of my stepper motor. It not even connected to a driver

The motor is creating it's own EMF when you try to turn the shaft manually. When coils are connected (or not connected) to any circuit that is not powered can cause unpredictable results. The motor freezing from just turning it by hand with no connection is surely the wires touching each other. This is actually how we test if a motor is good or bad. If the motor freezes when two of the wires are touching, that means the motor is functioning properly since the magnets are causing current to flow through that coil opposing the magnet.

-

I am using you reliable builder, though i am building from scratch. Can you help me size motors to my construction?

Sure, please describe the machine that you are building and the material with which the gantry and other parts will be built.

-

I am planning to build a scratch CNC machine to do rotary engraving on writing pens. Can you recommend the parts I would need? I'm thinking NEMA 14 (11?) and 3/8" acme rod. Not sure which linear motion to use. I have an old lathe to use for the 4th axis.

Consider the loads on each axis when choosing appropriate stepper motors. If your holding torque is maxed out at roughly 16oz/in (1lb/in), then you could use the NEMA 11 or 14. Also consider the shaft sizes and current ratings when choosing drivers that pair with the motors.

-

How do I wire two motors parallel

To have two stepper motors move simultaneously, connect the two stepper motor drivers to the same CP (step pulse) and CW (direction) pins for that axis. Additional Information: Can you send me a wiring diagram kkitching@hughes.net

-

How do I wire to nema 23 motors parallel

Wiring two motors in parallel is pretty easy. Here are the steps: - You need to have two stepper motors and two stepper motor drivers. - Each stepper motor will be connected to its own stepper motor driver. - Both stepper motor drivers are connected to the same CP and CW pins on the interface so the same signal is delivered to both drivers. Additional Information:

-

How do I connect my motor wires to the driver?

Use the datasheet associated to the motor that you purchased. Use the bipolar parallel configuration to optimum performance. The datasheets are located in their respective motor product pages. Just click on the motion electronics at the left and scroll down to the motor you have and click on the title, or datasheet link next to the motor. The datasheet will either be in the form of a pdf, or within the instructions on that product page. Additional Information: wiring diagram Additional Information: Additional Information:

-

HOW BAD IS THE SMOKE AND EXHAUST USING BLACKTOOTH?

I'll be honest, it can be pretty awful at times. You'll want a dedicated exhaust line. Cut a new hole, make a dedicated line. Also, invest in a charcoal air filter, it will help. Trust me. They can also be done DIY very inexpensively. Buy a "Universal Pre-filter" and simply wrap it around a screen and have air push down through the screen wrapped in the charcoal laden felt. $20 + fan + screen. Away you go =)