BuildYourCNC

Masso G3 Touch

Masso G3 Touch

Couldn't load pickup availability

The MASSO G3-Touch is a professional-grade, standalone CNC plasma controller featuring a sleek 15" capacitive touch LED screen. This cutting-edge system operates completely independently of a PC, eliminating the complexities of driver installation and motion cards. Simply connect the MASSO to your motor drives, input calibration values, and you're ready to begin machining.

Key Hardware Specifications:

- High-performance 110kHz pulse rate on each axis

- 24 isolated inputs for enhanced safety and reliability

- 18 outputs for comprehensive machine control

- 2 analog (12-bit) inputs for precise measurements

- Step & Direction signals supporting both stepper and servo drives

- MPG hand wheel dial support for manual control precision

- External THC module compatibility for torch height control

Connectivity and Integration: The G3-Touch features built-in WiFi capability, enabling wireless transfer of G-code files and real-time monitoring of machine and job status. Its thoughtful design allows for easy wiring, accessory installation, and maintenance while the unit remains mounted on the machine.

Technical Capabilities:

- Real-time motion control with high-speed processing

- Support for up to 6 axes of simultaneous motion control

- Advanced nesting capabilities for material optimization

- Compatible with major plasma cutting systems

- Integrated CAM software for DXF to G-code conversion

Software Features:

- Intuitive touchscreen interface with customizable workspaces

- Built-in shape library for common cutting patterns

- Comprehensive material database

- Real-time cut path visualization

- Automatic lead-in/lead-out generation

- Integrated diagnostics and troubleshooting tools

Safety and Control: The system incorporates robust safety features including emergency stop integration, voltage monitoring, and collision detection. Torch height control is precisely maintained through external THC modules, ensuring consistent cut quality across various material thicknesses.

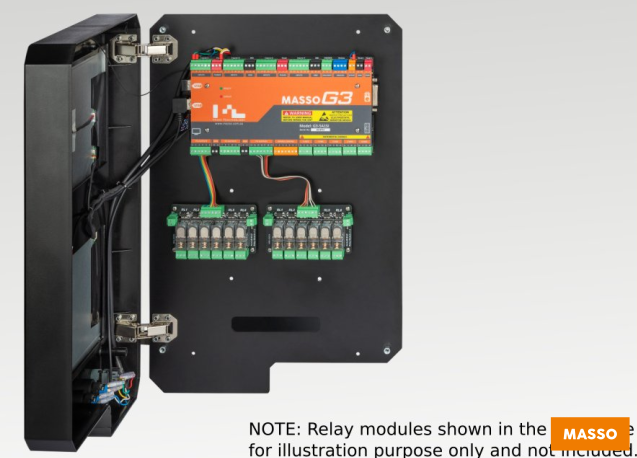

Durability and Design: Housed in a robust aluminum enclosure, the controller offers excellent heat dissipation and durability in demanding workshop environments. The 15" LED screen provides clear visibility of all operational parameters and cutting processes.

Installation and Support: Each unit includes:

- Detailed installation documentation

- Complete mounting hardware

- Access to technical support resources

- Built-in configuration wizards for quick setup

Ideal Applications:

- Professional fabrication workshops

- Production manufacturing facilities

- Educational institutions

- Prototype development centers

- Architectural metalwork shops

- Industrial manufacturing operations

The MASSO G3-Touch represents a complete, self-contained CNC plasma control solution that combines sophisticated capabilities with straightforward operation. Its standalone nature, coupled with advanced features and robust construction, makes it an ideal choice for businesses seeking a reliable, high-performance plasma cutting control system that doesn't require complex PC integration.

Share