BuildYourCNC

Round Female 4 pin 17mm NON-Threaded Spindle Connector

Round Female 4 pin 17mm NON-Threaded Spindle Connector

Couldn't load pickup availability

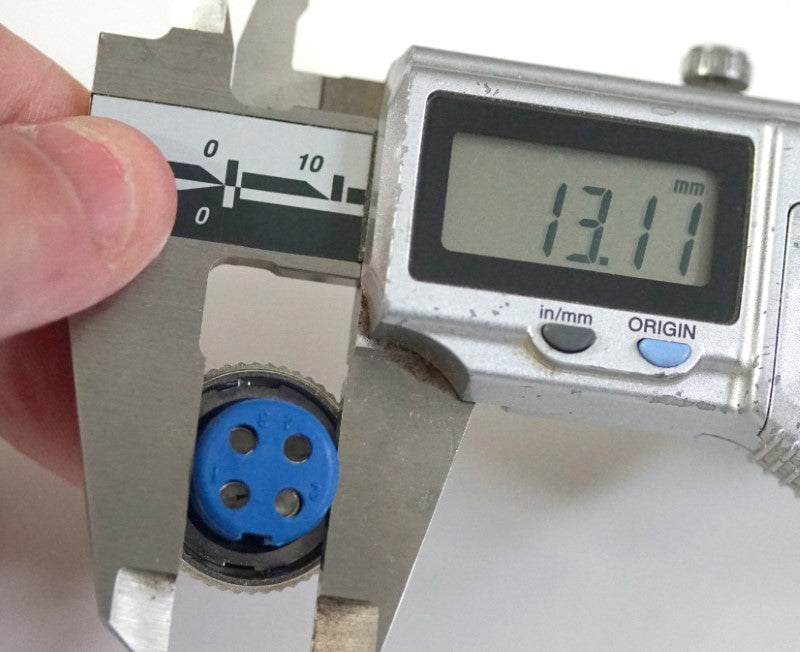

This is a 4 pin threaded connector also a replacement for typical spindles used in CNC routers and CNC machines but can be used in many other applications. This connector has four pins, just like the prongs on a plug. The space between each pin is about the same as the thickness of two quarters stacked together (0.2 inches or 5.08 mm). The whole connector is about the length of the short side of a business card (1.92 inches or 48.77 mm). How Much Power It Can Handle: It can carry an electric current similar to that of a small workshop tool, up to 5 amps. The amount of electric 'pressure' it can handle depends on how many wires you’re using. With 2 to 4 wires, it's strong like a big shop machine (up to 400 volts). With 5 to 8 wires, it's more like a standard power tool (up to 250 volts). Quality and Lifespan: The connector lets electricity flow through it very easily, without much loss – like a sharp chisel through soft wood. It’s really good at keeping electricity where it’s supposed to be, preventing it from 'leaking' out – think of it like a well-sealed varnish can. You can connect and disconnect it about 500 times before it starts to wear out, sort of like how a good saw blade lasts through many cuts. This connector is for the cable that connects to a Variable Frequency Drive (VFD), the device that controls the speed of your electric motors in the shop. The inside of the connector has four cup-like areas where you solder the wires. To establish a soldered connection between the cable and connector pins, follow these steps: Each pin features a cup-shaped lead on its rear end, designed to hold a pool of solder. Start by applying rosin core solder inside this cup. Also, tin the end of the wire that you'll insert into the cup by applying rosin core solder to it. Heat the cup already containing some solder, and while it's melted, insert the tinned wire into it. The use of rosin core solder on both the cup and wire end ensures that the flux aids in forming a strong solder bond between the two components.

Share

Questions & Answers

Have a Question?

-

I am looking to use this part to connect the spindle of a Bulkman ultimate 1500 and like to know if it would fit. It’s a 110 volt air cooled spindle. Thanks

The Bulkman Ultimate 1500 is a CNC platform and s not specific with what spindle is used. You can send a picture in the chat on this website and I can probably tell you if the connector will work.