BuildYourCNC

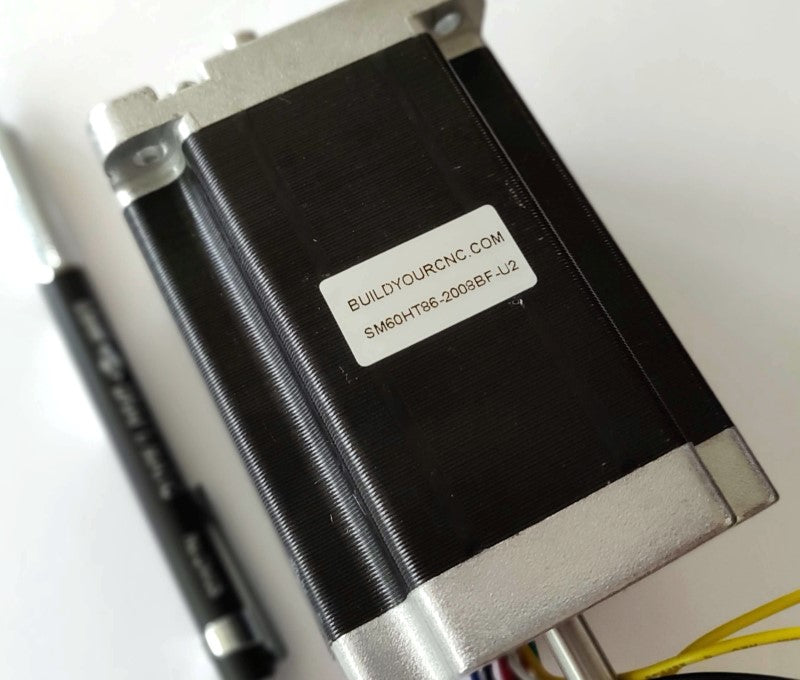

NEMA 23 Stepper Motor (425 oz-in 1/4" dual shaft) 2.8 Amps

NEMA 23 Stepper Motor (425 oz-in 1/4" dual shaft) 2.8 Amps

Couldn't load pickup availability

Affiliate Links

Description: NEMA 23 Stepper Motor 4.2A 3.0Nm (425oz.in) 100mm Length with 8mm Shaft

Price: $36.00 USD

See ProductShare

Questions & Answers

Have a Question?

-

What power supply would you recommend to run 3 of the stepper motors with the recommended driver?

For three of the NEMA 23 (425 oz-in) with the appropriate drivers, I would recommend the 48v 10 amp power supply.

-

I ordered two NEMA 23 steppers with 1/4" shafts, I received motors with 8mm shafts. I also ordered two 1/4" x 1/2" couplers, which I have not received. I have no problems with the motors, but I will need couplers to match the 8mm shaft to 1/2" lead screw.

I will send two 8mm to 1/2" couplings to you ASAP. Please send an email to customerservice@buildyourcnc.com so I can determine to whom to send the couings. Thanks. Additional Information: Please notice, I followed up with several emails abut this situation. In one, I corrected the motor shaft sizes to 10mm. I understand that, as a result of my emails, the original 1/4" x 1/2" couplers were sent and apparently received by someone at the wrong address. As of this time, I have received no couplers of any size and have gotten no reponses to my emails. Can you enlighten me? Additional Information: I looked all throughout my email and I cannot find an email from you. Please send an email to phooddaniel@gmail.com so I can determine who this is and to whom I need to send the new couplings. Thanks

-

There are 8 wires on this motor. How do you connect to the driver?

If the motor has 8 wires, you will need to wire the stepper motor in bipolar parallel. This motor (425 oz-in) is wired as follows: Red and Blue wires to A+ on driver Yellow and Black wires to A- on driver White and Brown wires to B+ on driver Orange and Green wires to B- on driver

-

I have two of these motors, both purchased recently as part of the heavy gantry 3-axis combo. They are warm to the touch when not doing anything. Is this normal? They work when jogged w/mach4

It is normal for stepper motors to get hot to the touch while not moving. There is a setting on the driver that you can set to half current. This is an idle current while the motor is just in a holding position.