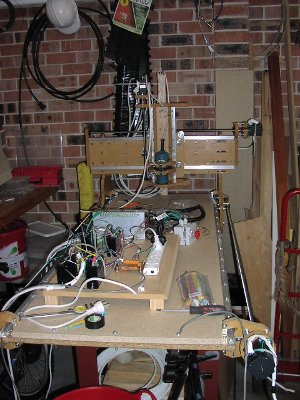

Michael G's CNC Build in Australia

It is all that I

expected it to be!

It is all that I

expected it to be!

The system actually worked first time, just a small mix up on the ENABLE pin of

the stepper drivers, I thought they were active high but actually active low or

open circuit. Otherwise I just needed to make sure the Mach3 config entries were

entered correctly and I was up and running with theory matching practical setup

entries.

I have added 6 limit switches, 3 of these are used for homing as well. The Z--limit

switch is adjustable however by using Soft Limits this is not absolutely necessary.

I will keep it as a back up as I sometimes turn off rather than reset the Softlimits

for jobs. I have also added an additional dust collector, still working on the best

route for the air hose.

Machine accuracy is very good, repeatability is very good. (I am still determining

ultimate accuracy, but definielty better than 0.05mm with theoretical accuracy of

0.001mm)

I did have a problem with the long lead screws as they were a little bent. This

most likely occured during assembly of components and me leaning up against them,

but they were easy to remove and straighten.

I have kept the feed rate to a max of 120in/min for now which is more than enough

so far, which helps reduce and residual whipping in the long lead screws.

Mach3 is great, it has all the functions and features needed, plus more and I am

running successfully on an old rescued PC.

For the few small trial jobs I have done the 500W trimmer is doing just fine. I

have purchased some small 6mm collect router bits and will be running some samples

from the Vcarve trial software packages before leaping into anything else at this

time.

Future......I will need to add a motor speed controller if I plan to do other materials

than wood, or continue the search for other router/trimmer solutions.

All in all, I think that this is a great kit to build and learn about the world

of CNC and end up with something that does a realy good job.